Cat. No. I129E-EN-01

MX2

Born to drive machines

Model: MX2

200 V Class Three-Phase Input 0.1 to 15 kW

200 V Class Single-Phase Input 0.1 to 2.2 kW

400 V Class Three-Phase Input 0.4 to 15 kW

QUICK START GUIDE

MX2 Quick Start Guide

1 SPECIFICATIONS

3

1.1 Upon receipt

3

1.2 Technical specification

4

1.3 Power ratings

4

2 INSTALLATION

6

2.1 Wiring sizes and protection

6

2.2 External dimensions for installation (IP20 & IP54)

6

2.3 Installation Environment clearance

9

2.4 Wiring overview

10

2.5 Power wiring

11

2.6 Control wiring

11

2.7 Screwless terminals connection

12

2.8 Digital inputs SINK/SOURCE (NPN/PNP) settings

13

2.9 Safe stop disable function

13

3 PROGRAMMING MX2

.....................................................................14

3.1 Digital operator

14

3.2 Keypad navigation

15

3.3 Initialization

15

3.4 Inverter modes

16

3.5 Basic settings

17

3.6 Auto tuning (SLV Mode)

18

3.7 Ramps adjustment

20

3.8 DC Braking

21

3.9 V/F Curve

22

3.10 Torque boost function

23

3.11 Analog inputs

24

3.12 Digital inputs

25

3.13 Digital outputs

27

3.14 Pulse input

29

3.15 Analogue and pulse outputs

30

3.16 Torque limit

30

3.17 Torque control

31

3.18 Electronic thermal overload

31

3.19 Carrier frequency (PWM)

32

3.20 PID Function

33

3.21 Current limitation functions

33

3.22 Overvoltage protection

34

3.23 Controlled stop at power loss

35

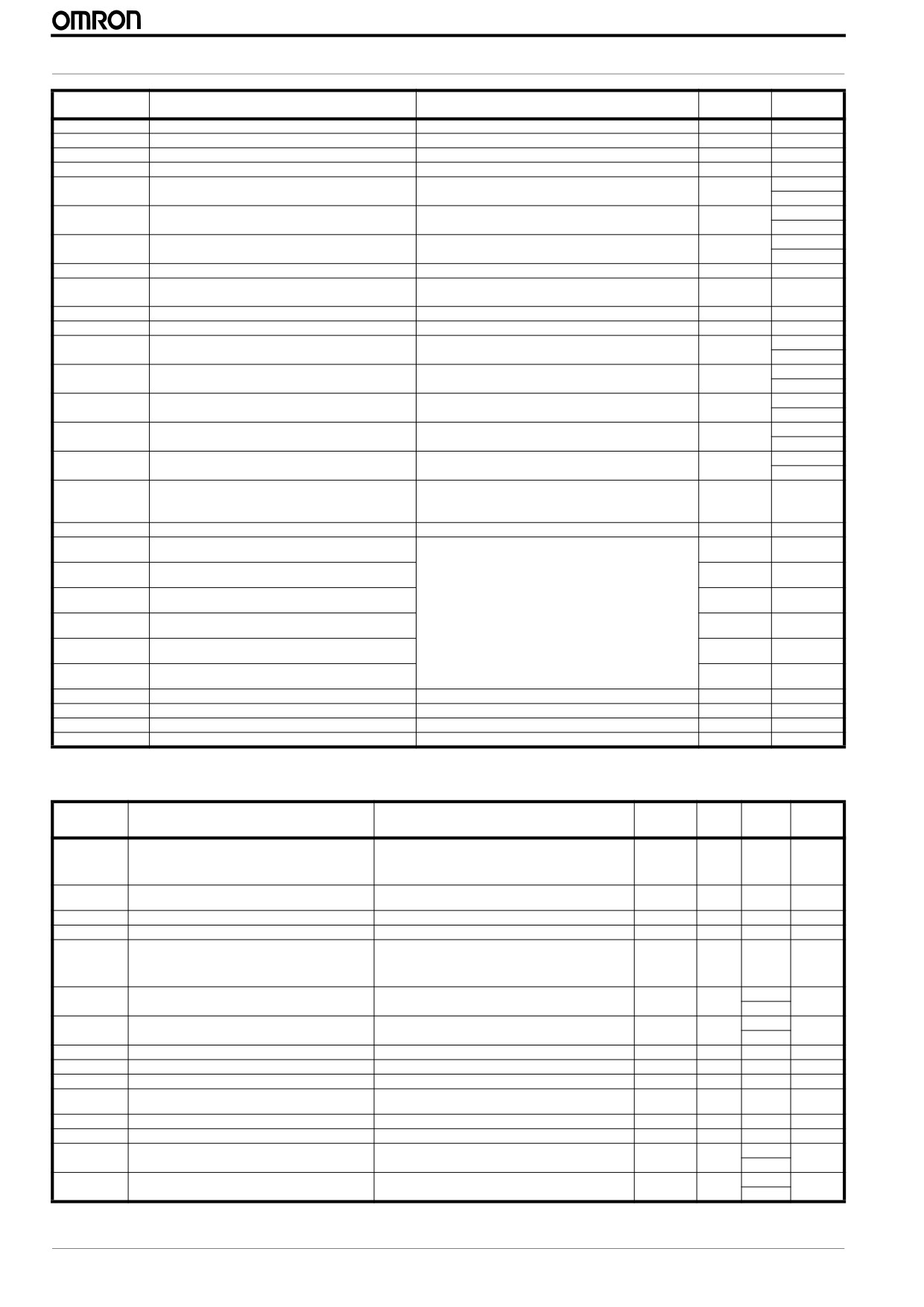

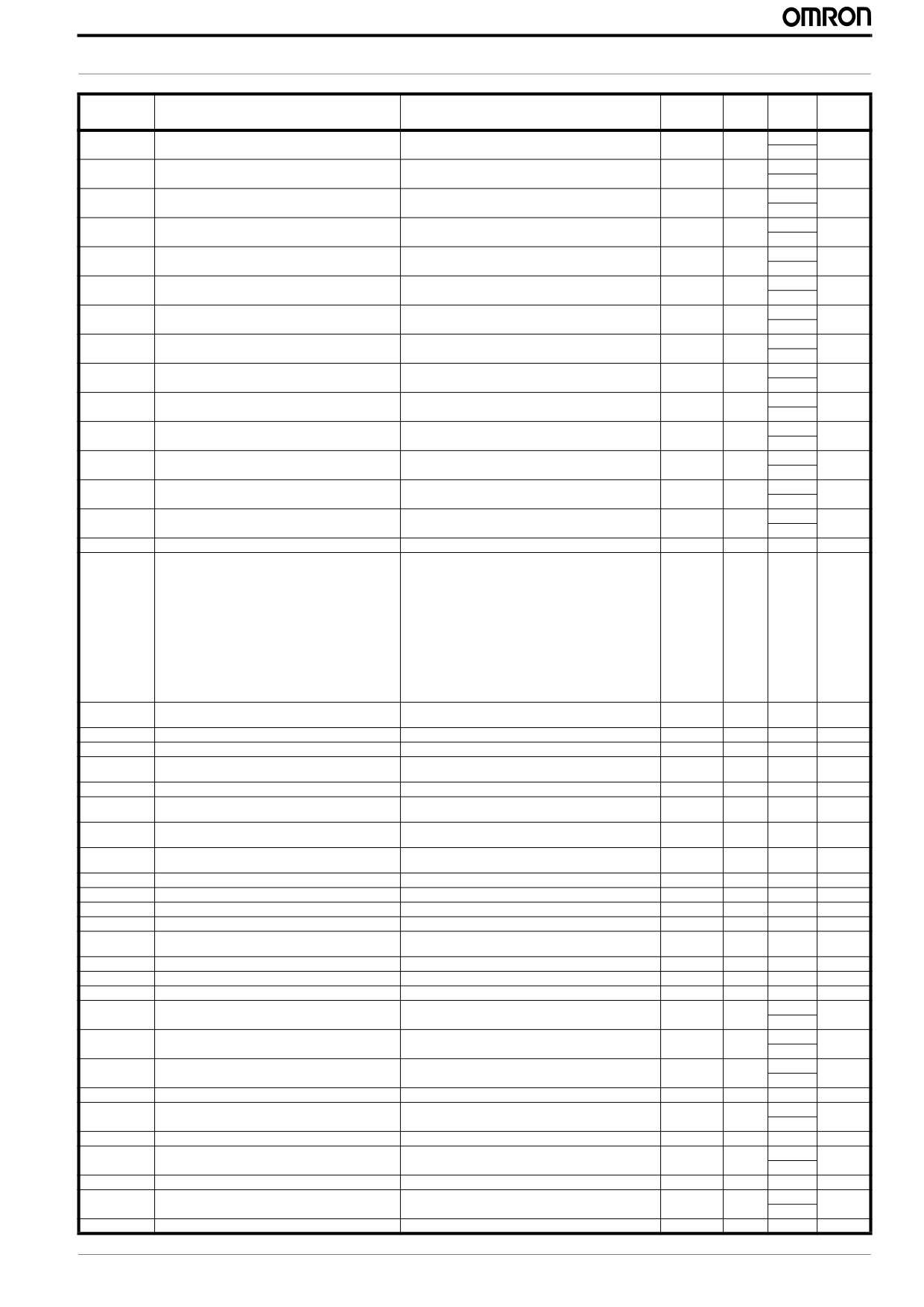

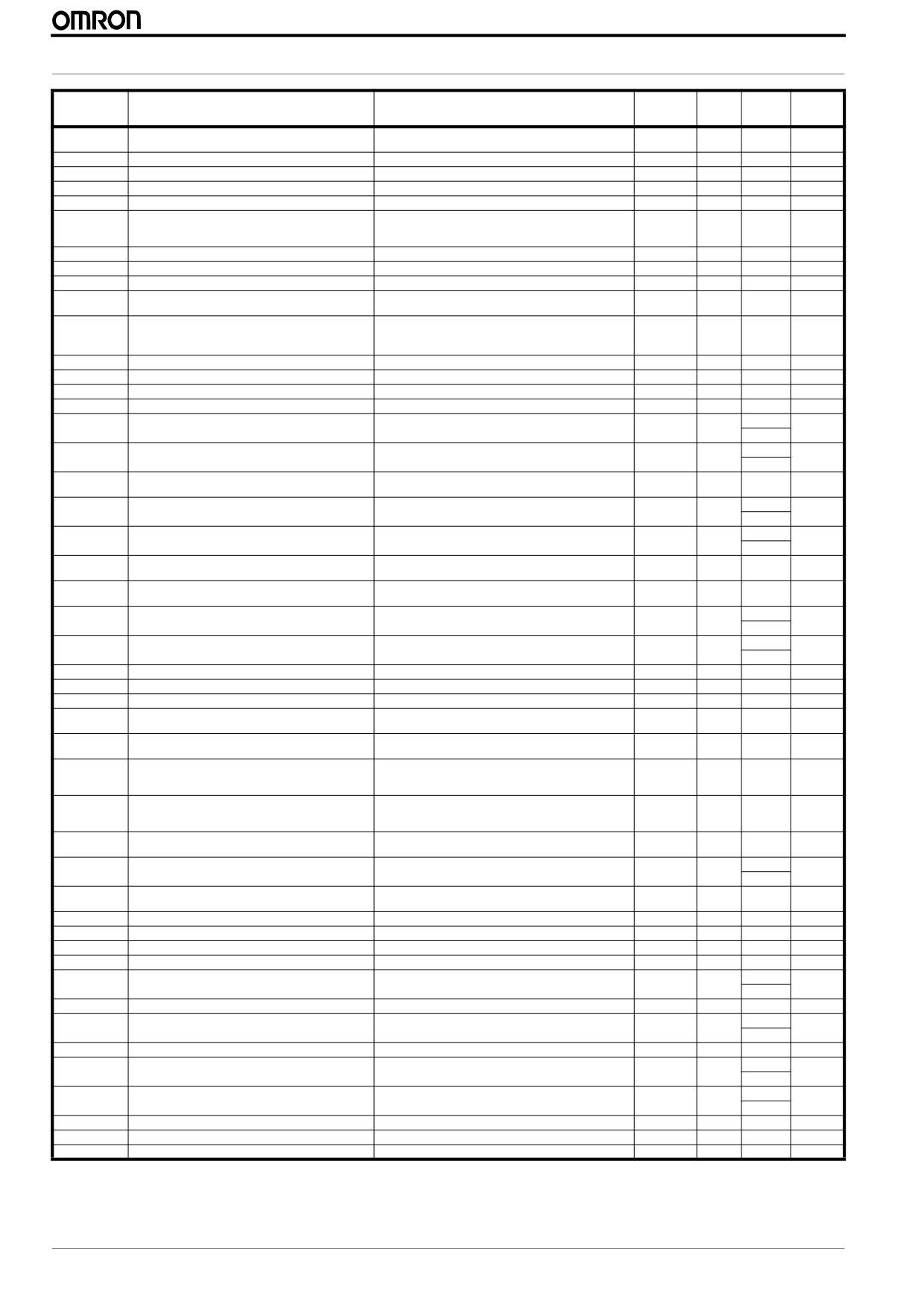

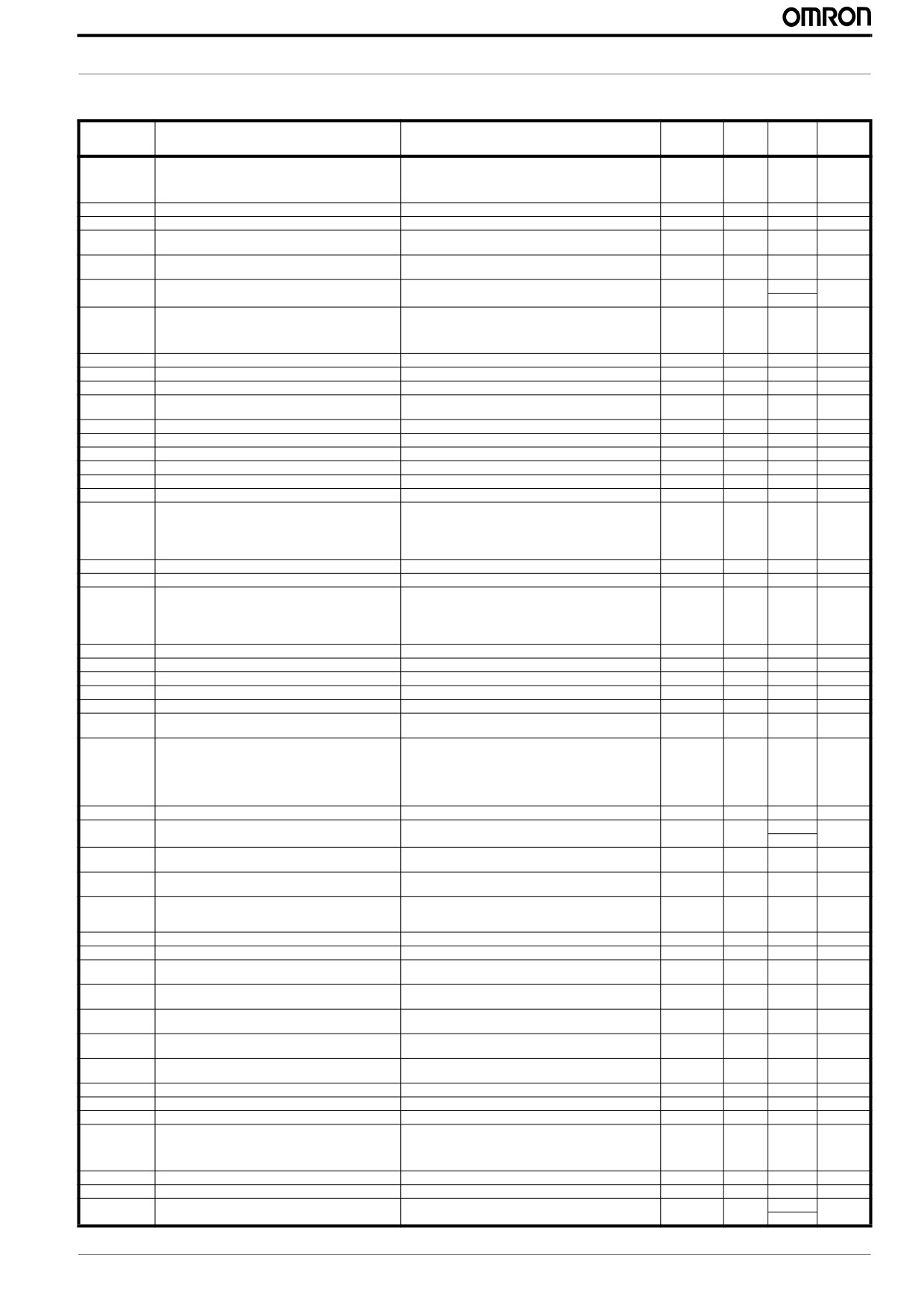

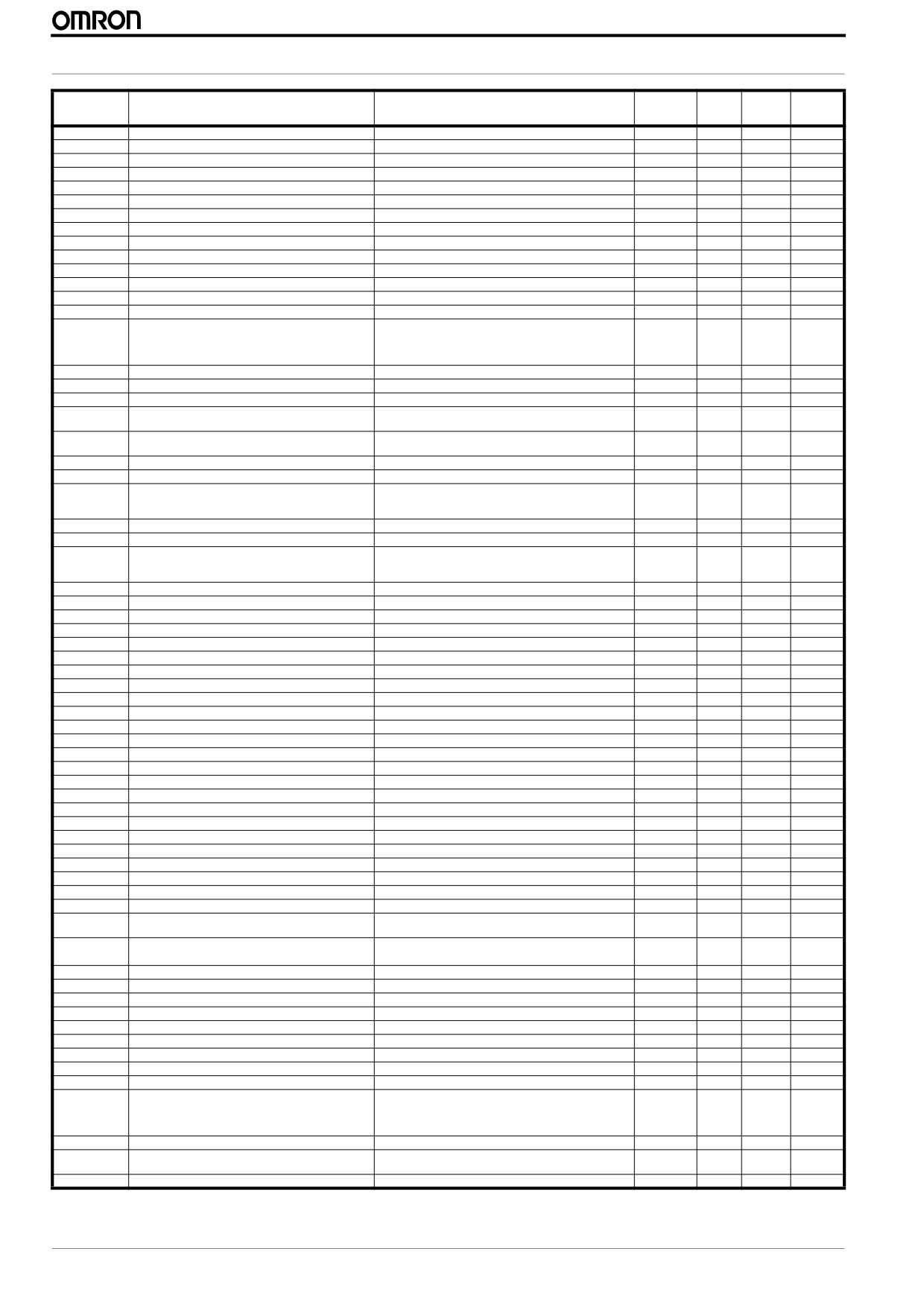

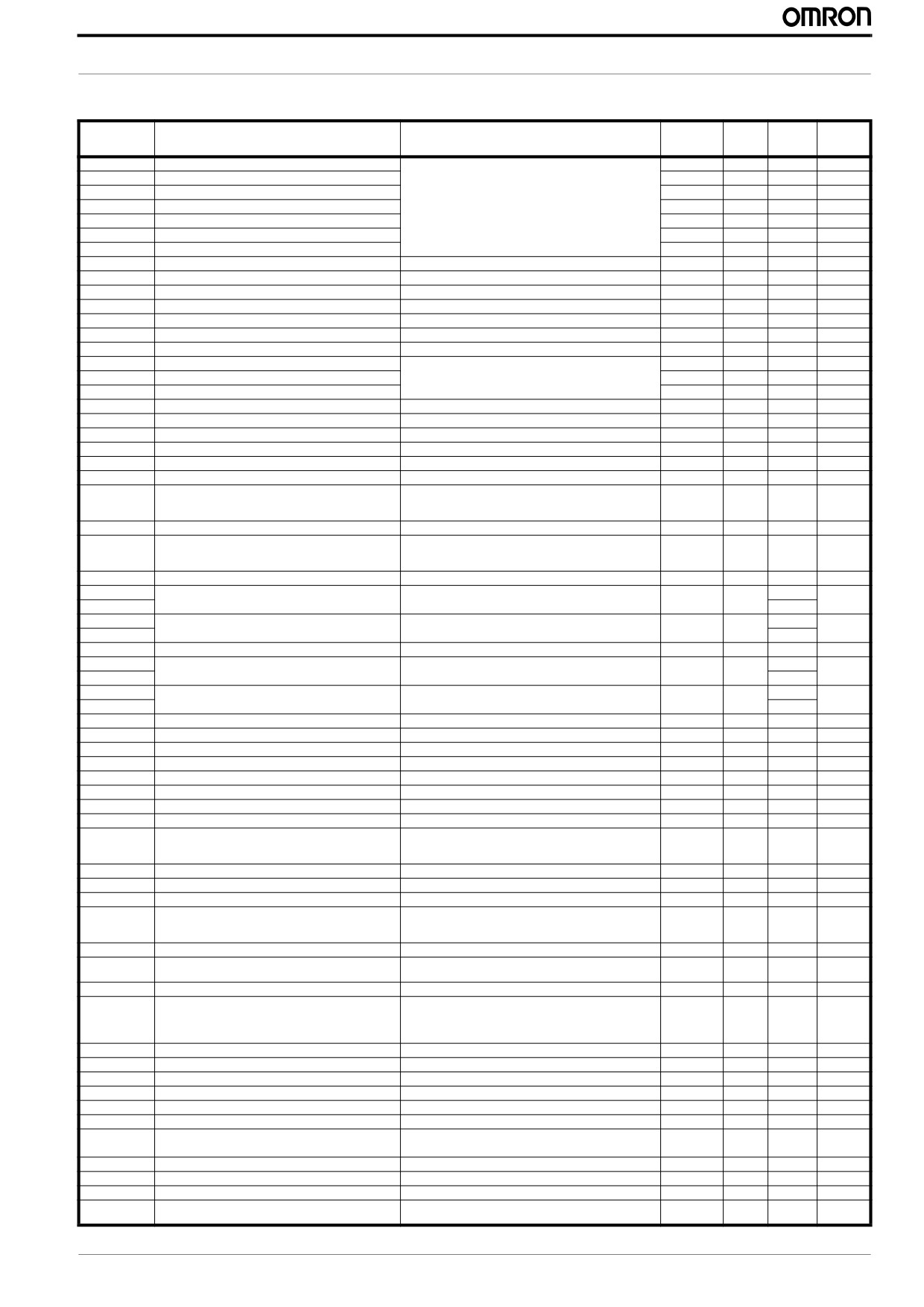

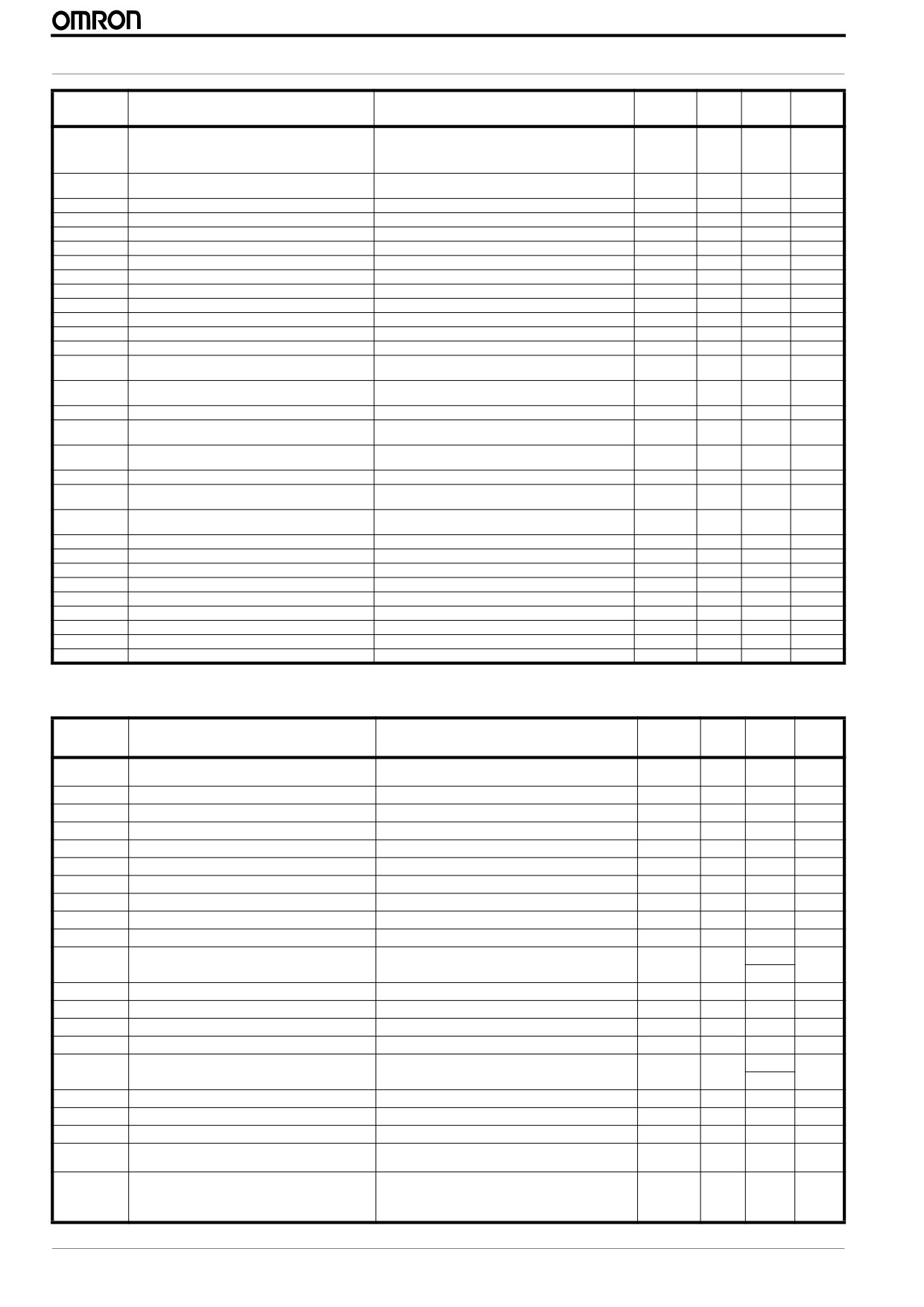

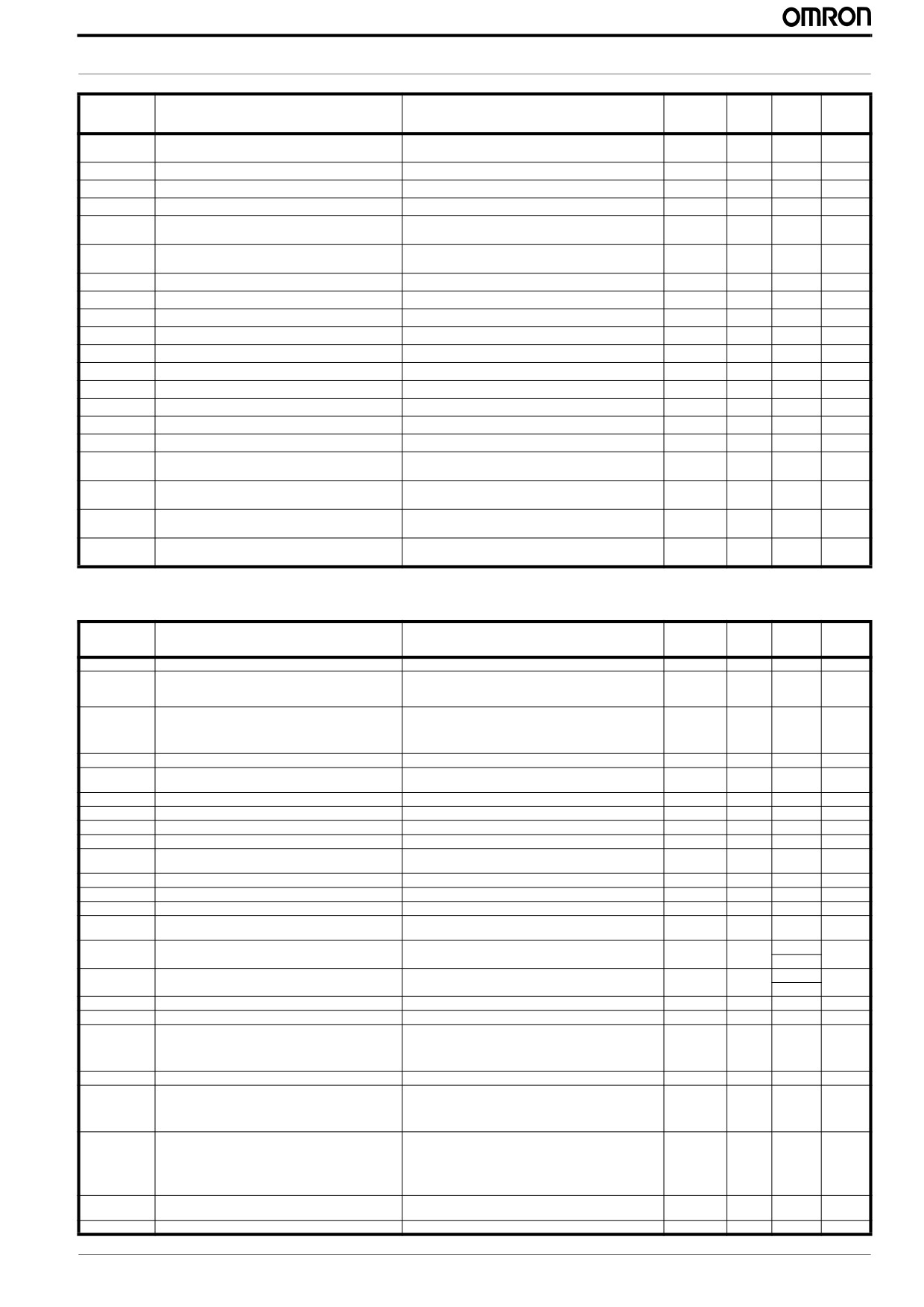

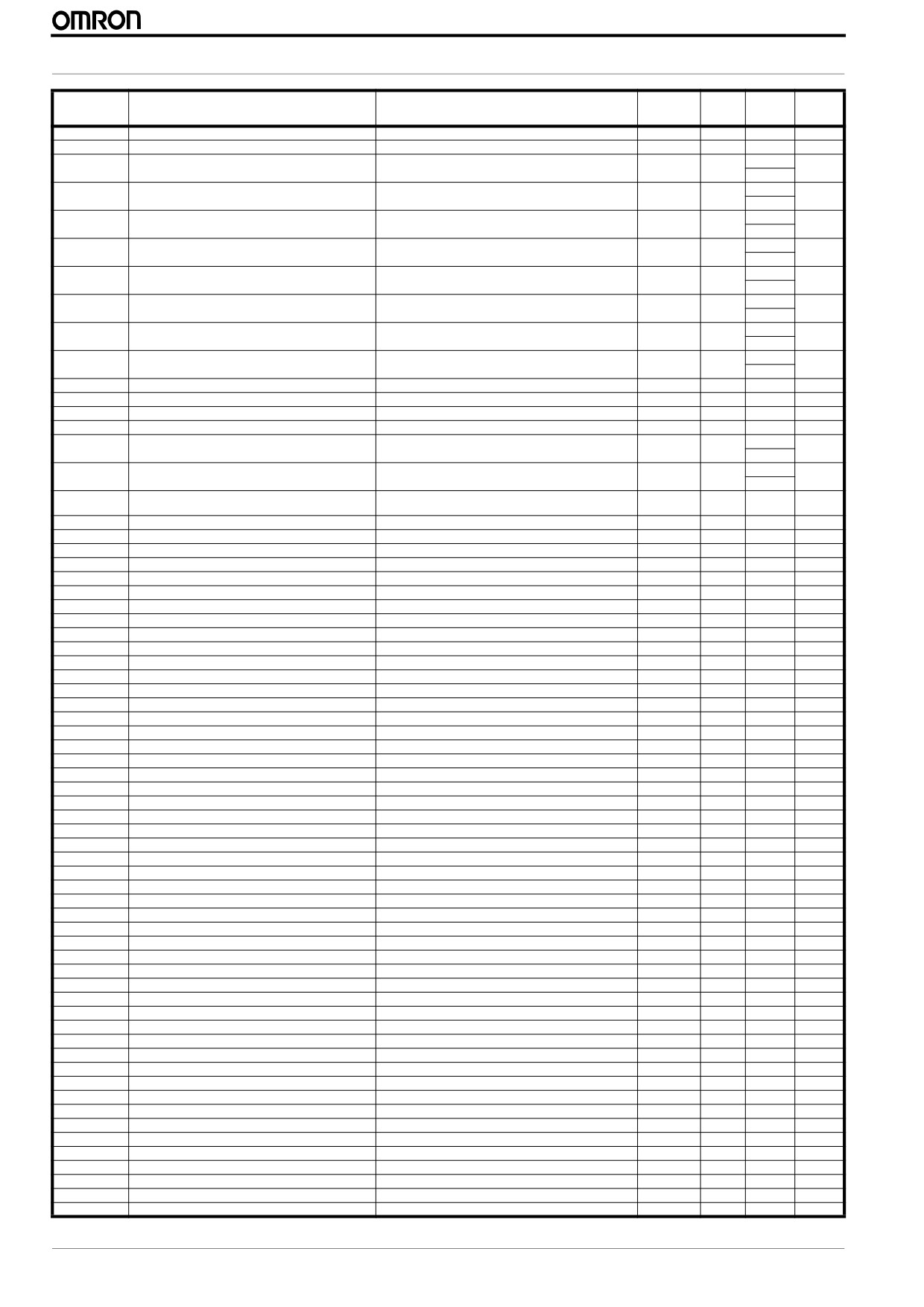

4 PARAMETER LIST

35

4.1 Parameter group D: Monitors

35

4.2 Parameter group A

36

4.3 Parameter group B

39

4.4 Parameter group C

41

4.5 Parameter group H

42

4.6 Parameter group P

43

4.7 Parameter group F

45

4.8 Parameter group U: User parameters

45

MX2 Quick Start Guide Draft

1

2

MX2 Quick Start Guide Draft

MX2 Quick Start Guide

1 SPECIFICATIONS

1.1 Upon receipt

Please perform the following task after receiving the drive:

• Inspect the driver for damage. If the drive appears to be damaged upon receipt, contact your supplier

• Verify the receipt of the correct model by checking the information on the nameplate. If you have received the wrong model

contact your supplier.

• Refer to the User’s Manual for detailed information about the product and functions

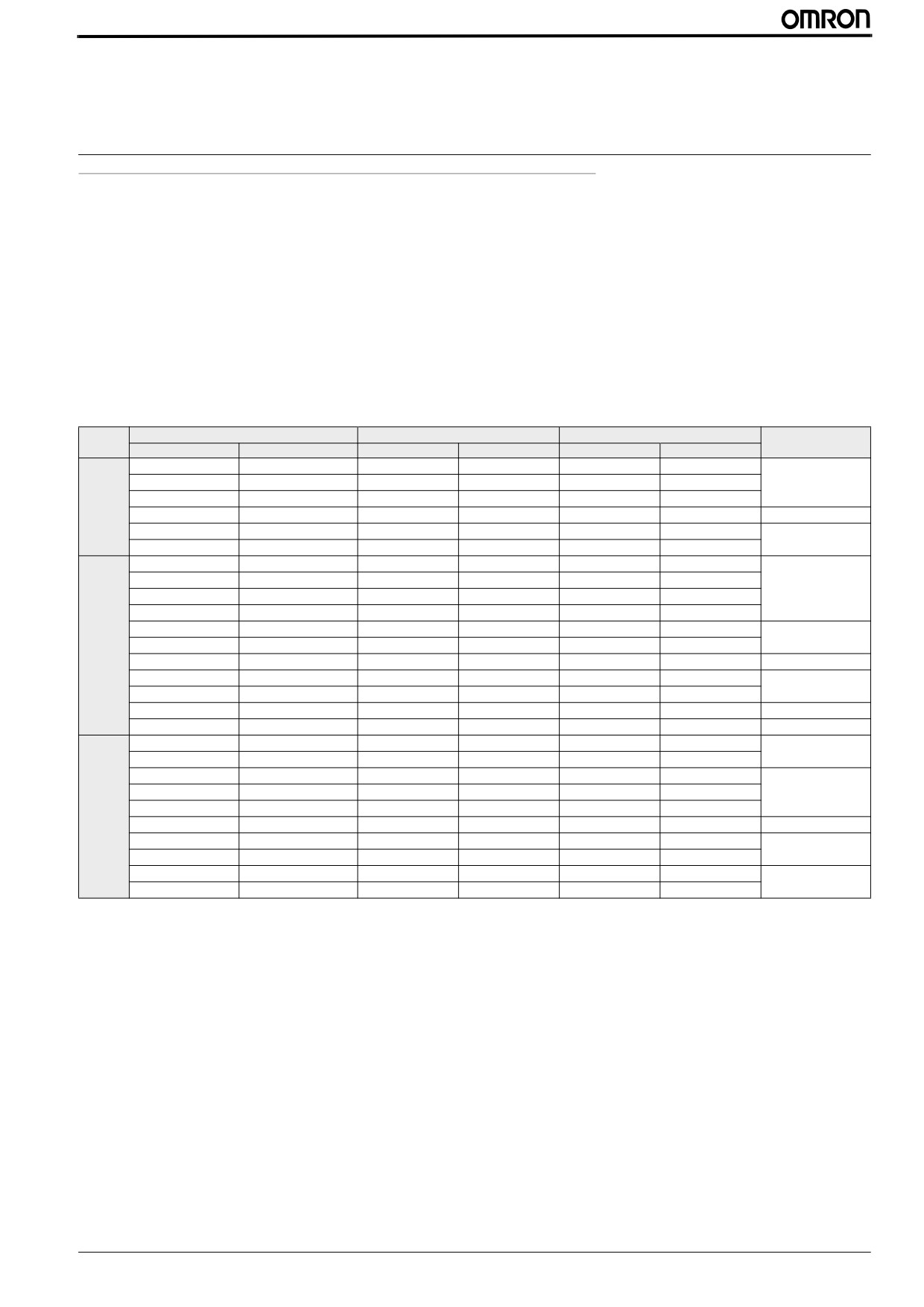

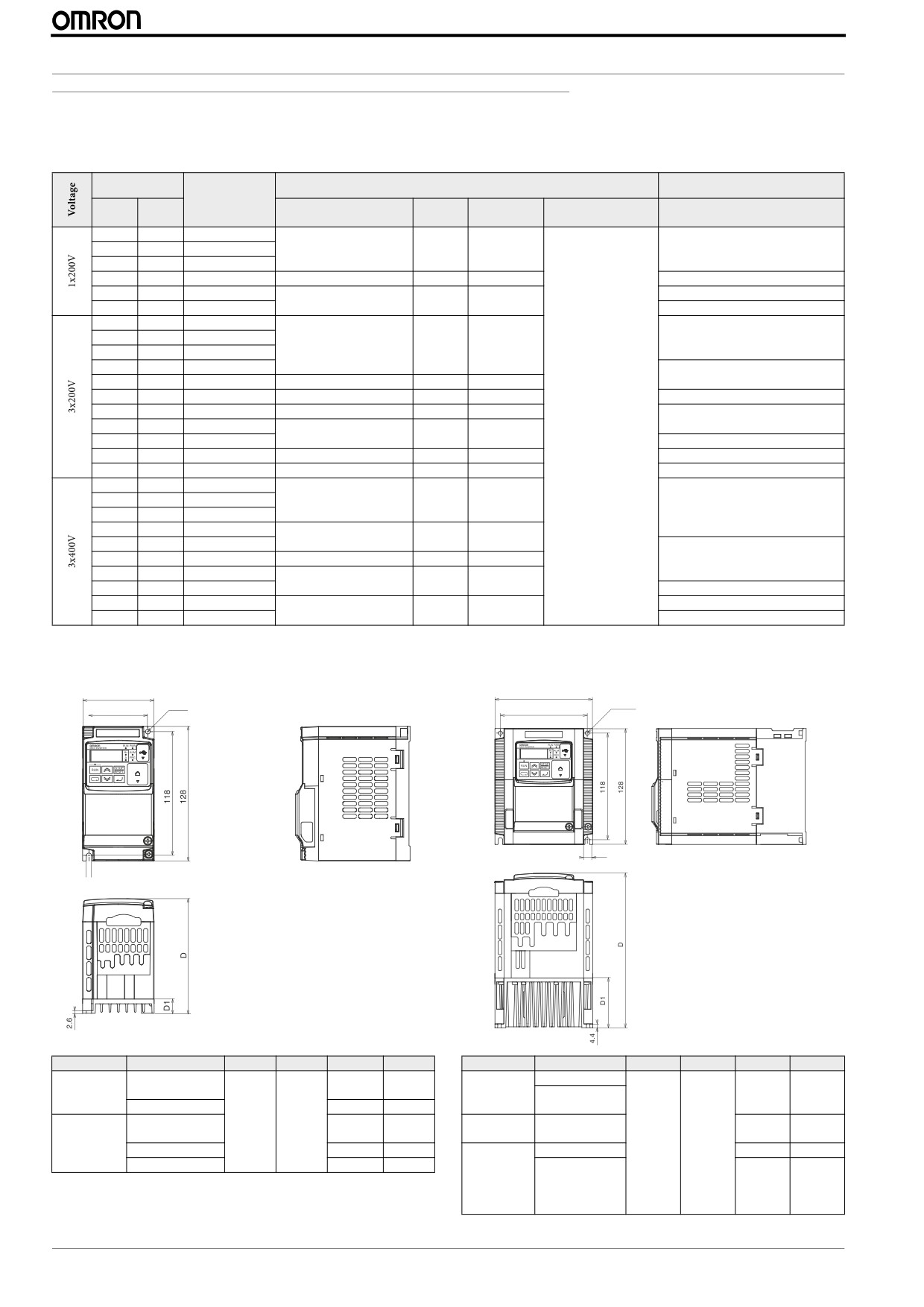

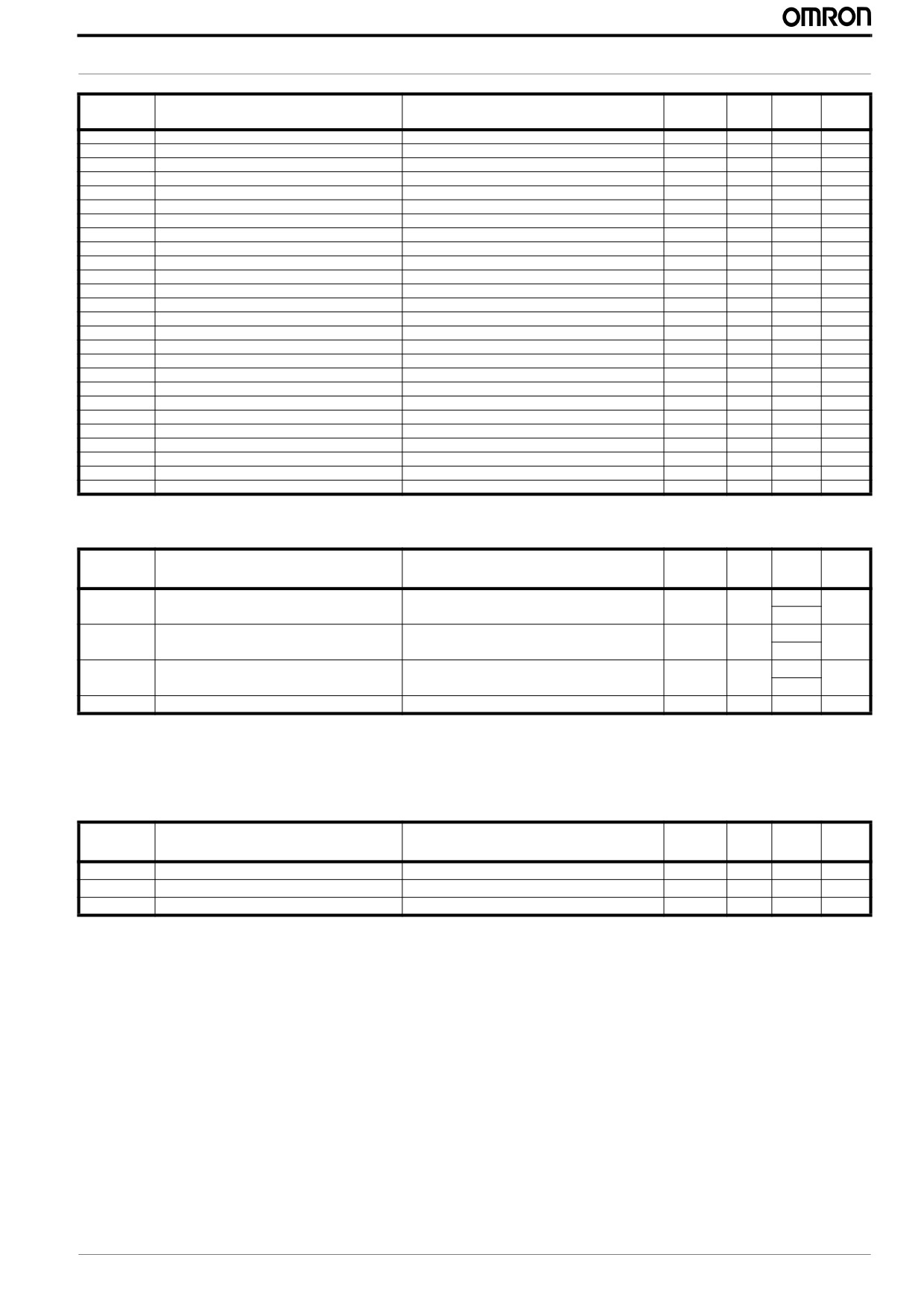

Basic specifications and EMC filter

Type

HD (150% overload for 60s)

ND (120% overload for 60s)

Voltage

EMC filter*

IP20

IP54

Max Motor (KW)

Rated current (A)

Max Motor (KW)

Rated current (A)

3G3MX2-AB001-E

3G3MX2-DB001-E/EC

0.1

1.0

0.2

1.2

AX-FIM1010-RE

3G3MX2-AB002-E

3G3MX2-DB002-E/EC

0.2

1.6

0.4

1.9

AX-FIM1014-SE

3G3MX2-AB004-E

3G3MX2-DB004-E/EC

0.4

3.0

0.55

3.5

1 x 230 V

3G3MX2-AB007-E

3G3MX2-DB007-EC

0.75

5.0

1.1

6.0

AX-FIM1014-RE/SE

3G3MX2-AB015-E

3G3MX2-DB015-EC

1.5

8.0

2.2

9.6

AX-FIM1024-RE/SE

3G3MX2-AB022-E

3G3MX2-DB022-EC

2.2

11.0

3.0

12.0

3G3MX2-A2001-E

3G3MX2-D2001-E/EC

0.1

1.0

0.2

1.2

3G3MX2-A2002-E

3G3MX2-D2002-E/EC

0.2

1.6

0.4

1.9

AX-FIM2010-RE/SE

3G3MX2-A2004-E

3G3MX2-D2004-E/EC

0.4

3.0

0.55

3.5

3G3MX2-A2007-E

3G3MX2-D2007-E/EC

0.75

5.0

1.1

6.0

3G3MX2-A2015-E

3G3MX2-D2015-EC

1.5

8.0

2.2

9.6

AX-FIM2020-RE/SE

3 x 230 V

3G3MX2-A2022-E

3G3MX2-D2022-EC

2.2

11.0

3.0

12.0

3G3MX2-A2037-E

3G3MX2-D2037-EC

3.7

17.5

5.5

19.6

AX-FIM2030-RE/SE

3G3MX2-A2055-E

3G3MX2-D2055-EC

5.5

25.0

7.5

30.0

AX-FIM2060-RE/SE

3G3MX2-A2075-E

3G3MX2-D2075-EC

7.5

33.0

11

40.0

3G3MX2-A2110-E

3G3MX2-D2110-EC

11

47.0

15

56.0

AX-FIM2080-RE/SE

3G3MX2-A2150-E

3G3MX2-D2150-EC

15

60.0

18.5

69.0

AX-FIM2100-RE/SE

3G3MX2-A4004-E

3G3MX2-D4004-EC

0.4

1.8

0.75

2.1

AX-FIM3005-RE/SE

3G3MX2-A4007-E

3G3MX2-D4007-EC

0.75

3.4

1.5

4.1

3G3MX2-A4015-E

3G3MX2-D4015-EC

1.5

4.8

2.2

5.4

3G3MX2-A4022-E

3G3MX2-D4022-EC

2.2

5.5

3.0

6.9

AX-FIM3010-RE/SE

3G3MX2-A4030-E

3G3MX2-D4030-EC

3.0

7.2

4.0

8.8

3 x 400 V

3G3MX2-A4040-E

3G3MX2-D4040-EC

4.0

9.2

5.5

11.1

AX-FIM3014-RE/SE

3G3MX2-A4055-E

3G3MX2-D4055-EC

5.5

14.8

7.5

17.5

AX-FIM3030-RE/SE

3G3MX2-A4075-E

3G3MX2-D4075-EC

7.5

18.0

11

23.0

3G3MX2-A4110-E

3G3MX2-D4110-EC

11

24.0

15

31.0

AX-FIM3050-RE/SE

3G3MX2-A4150-E

3G3MX2-D4150-EC

15

31.0

18.5

38.0

* 3G3MX2-D types include a built in EMC filter

MX2 Quick Start Guide Draft

3

MX2 Quick Start Guide

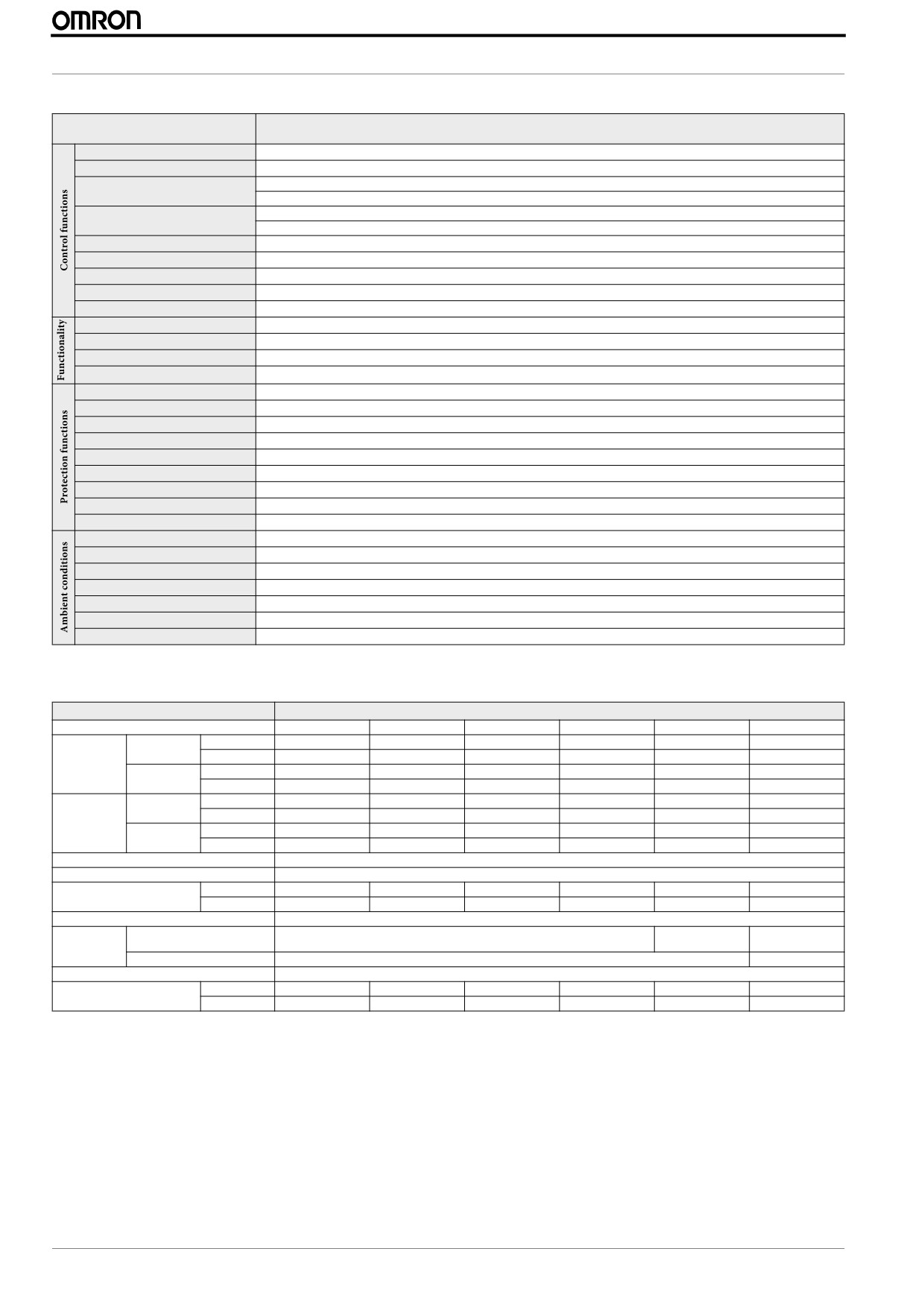

1.2 Technical specification

Model number

Specifications

MX2

Control methods

Phase-to-phase sinusoidal pulse with modulation PWM (Sensorless vector control, V/F)

Output frequency range

0.10..1000.00 Hz (with restrictions above 400Hz)

Digital set value: ±0.01% of the max. frequency

Frequency precision

Analogue set value: ±0.2% of the max. frequency (25 ±10 ºC)

Digital set value: 0.01 Hz

Resolution of frequency set value

Analogue set value: 1/1000 of maximum frequency

Resolution of output frequency

0.01Hz

Starting torque

200% / 0.5Hz

Overload capability

Dual rating: Heavy duty (CT): 150% for 1 minute

/ Normal Duty (VT): 120% for 1 minute

Frequency set value

0 to 10 VDC (10KW), 4 to 20mA (100W), RS485 Modbus, Network options

V/f Characteristics

Constant/ reduced torque, free V/f

Analogue inputs

2 analogue inputs 0 to 10V (10KW), 4 to 20mA (100W)

Pulse train input terminal

0 to 10V (up to 24V), up to 32KHz

Accel/Decel times

0.01 to 3600.0s (line/curve selection), 2nd accel/decel setting available

Display

Status indicator LED’s Run, Program, Alarm, Power, Hz, Amps

Motor overload protection

Electronic Thermal overload relay and PTC thermistor input

Instantaneous overcurrent

200% of rated current

Overload

Dual rating: Heavy duty (CT): 150% for 1 minute

/ Normal Duty (VT): 120% for 1 minute

Overvoltage

800V for 400V type and 400V for 200V type

Undervoltage

345V for 400V type and 172.5V for 200V type

Momentary power loss

Following items are selectable: Alarm, decelerates to stop, decelerates to stop with DC bus controlled, restart

Cooling fin overheat

Temperature monitor and error detection

Stall prevention level

Stall prevention during acceleration/deceleration and constant speed

Ground fault

Detection at power-on

Degree of protection

IP20, Varnish coating on PCB & IP54 (For 3G3MX2-D@ type)

Ambient humidity

90% RH or less (without condensation)

Storage temperature

-20 ºC..+65 ºC (short-term temperature during transportation)

Ambient temperature

-10°C to 50°C (Output current derating could be necessary above 40ºC or depending on installation conditions)

Installation

Indoor (no corrosive gas, dust, etc.)

Installation height

Max. 1000 m

Vibration

5.9 m/s2 (0.6G), 10 to 55 Hz

1.3 Power ratings

Item

Single-phase 200 V class Specifications

MX2 inverters, 200 V models

AB001

AB002

AB004

AB007

AB015

AB022

VT

0.2

0.4

0.55

1.1

2.2

3.0

kW

Applicable

CT

0.1

0.2

0.4

0.75

1.5

2.2

motor size

VT

1/4

1/2

3/4

1.5

3

4

HP

CT

1/8

1/4

1/2

1

2

3

VT

0.4

0.6

1.2

2.0

3.3

4.1

200 V

Rated capacity

CT

0.2

0.5

1.0

1.7

2.7

3.8

(kVA)

VT

0.4

0.7

1.4

2.4

3.9

4.9

240 V

CT

0.3

0.6

1.2

2.0

3.3

4.5

Rated input voltage

Single-phase: 200 V-15% to 240 V+10%, 50/60 Hz±5%

Rated output voltage

3-phase: 200 to 240 V (proportional to input voltage)

VT

1.2

1.9

3.5

6.0

9.6

12.0

Rated output current (A)

CT

1.0

1.6

3.0

5.0

8.0

11.0

Starting torque

200% at 0.5 Hz

100%: at50 Hz

70%: at 50 Hz

20%: at 50 Hz

Without resistor

Braking

50%: at 60 Hz

50%: at 60 Hz

20%: at 60 Hz

With resistor

150%

100%

DC braking

Variable operating frequency, time, and braking force

kg

1.0

1.0

1.1

1.4

1.8

1.8

Weight

lb

2.2

2.2

2.4

3.1

4.0

4.0

4

MX2 Quick Start Guide Draft

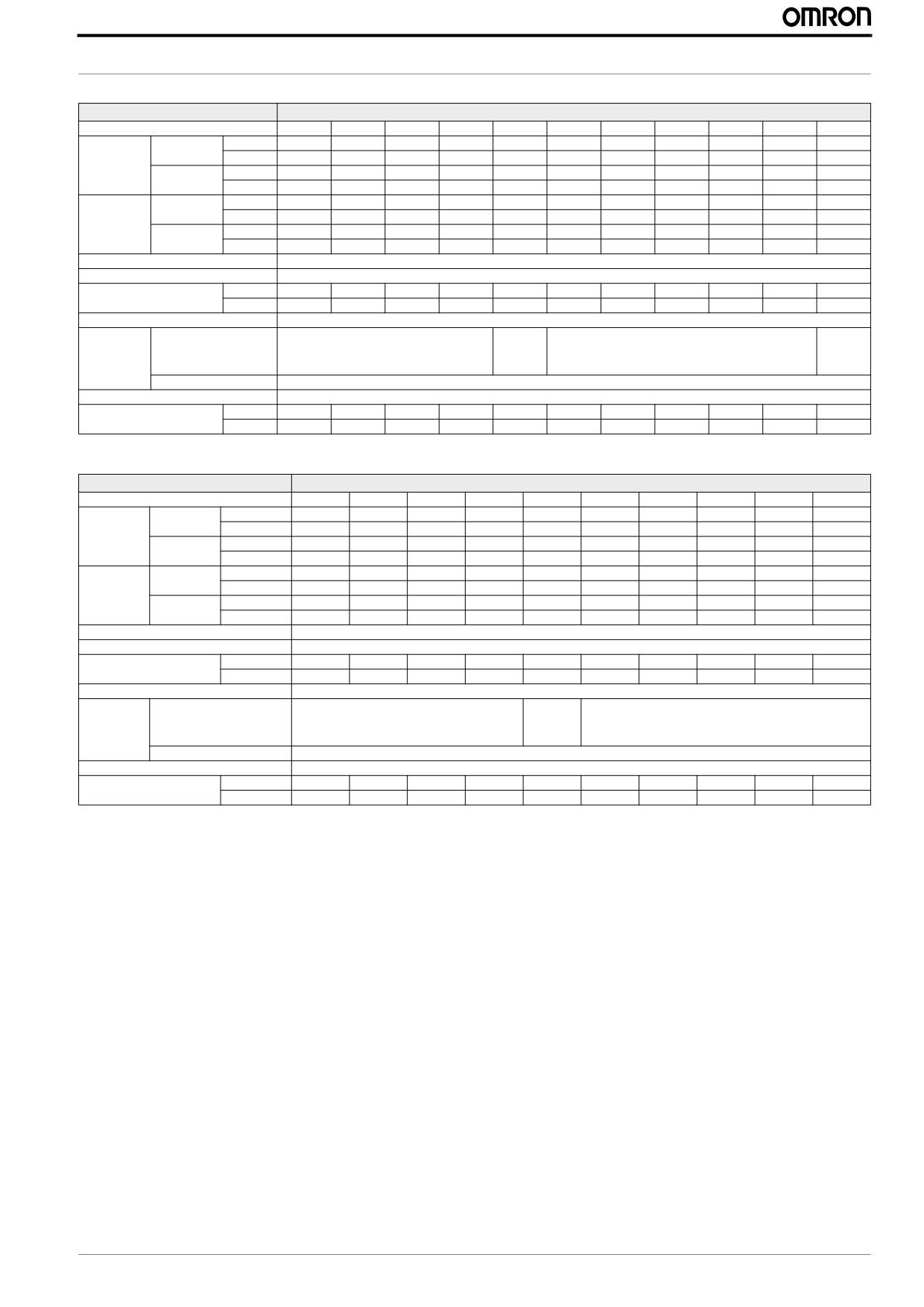

SPECIFICATIONS

Item

Three-phase 200V class Specifications

MX2 inverters, 200 V models

A2001

A2002

A2004

A2007

A2015

A2022

A2037

A2055

A2075

A2110

A2150

VT

0.2

0.4

0.75

1.1

2.2

3.0

5.5

7.5

11

15

18.5

kW

Applicable

CT

0.1

0.2

0.4

0.75

1.5

2.2

3.7

5.5

7.5

11

15

motor size

VT

1/4

1/2

1

1.5

3

4

7.5

10

15

20

25

HP

CT

1/8

1/4

1/2

1

2

3

5

7.5

10

15

20

VT

0.4

0.6

1.2

2.0

3.3

4.1

6.7

10.3

13.8

19.3

23.9

200 V

Rated

CT

0.2

0.5

1.0

1.7

2.7

3.8

6.0

8.6

11.4

16.2

20.7

capacity (kVA)

VT

0.4

0.7

1.4

2.4

3.9

4.9

8.1

12.4

16.6

23.2

28.6

240 V

CT

0.3

0.6

1.2

2.0

3.3

4.5

7.2

10.3

13.7

19.5

24.9

Rated input voltage

Three-phase: 200 V-15% to 240 V+10%, 50/60 Hz±5%

Rated output voltage

Three-phase: 200 to 240 V (proportional to input voltage)

VT

1.2

1.9

3.5

6.0

9.6

12.0

19.6

30.0

40.0

56.0

69.0

Rated output current (A)

CT

1.0

1.6

3.0

5.0

8.0

11.0

17.5

25.0

33.0

47.0

60.0

Starting torque

200% at 0.5 Hz

70%: at

100%: at

100%: at 50 Hz

50 Hz

100%: at 50 Hz

50 Hz

Without resistor

Braking

50%: at 60 Hz

50%: at

50%: at 60 Hz

50%: at

60 Hz

60 Hz

With resistor

150%

DC braking

Variable operating frequency, time, and braking force

kg

1.0

1.0

1.1

1.2

1.6

1.8

2.0

3.3

3.4

5.1

7.4

Weight

lb

2.2

2.2

2.4

2.6

3.5

4.0

4.4

7.3

7.5

11.2

16.3

Item

Three-phase 400V class Specifications

MX2 inverters, 400 V models

A4004

A4007

A4015

A4022

A4030

A4040

A4055

A4075

A4110

A4150

VT

0.75

1.5

2.2

3.0

4.0

5.5

7.5

11

15

18.5

kW

Applicable

CT

0.4

0.75

1.5

2.2

3.0

4.0

5.5

7.5

11

15

motor size

VT

1

2

3

4

5

7.5

10

15

20

25

HP

CT

1/2

1

2

3

4

5

7.5

10

15

20

VT

1.3

2.6

3.5

4.5

5.7

7.3

11.5

15.1

20.4

25.0

380 V

Rated capacity

CT

1.1

2.2

3.1

3.6

4.7

6.0

9.7

11.8

15.7

20.4

(kVA)

VT

1.7

3.4

4.4

5.7

7.3

9.2

14.5

19.1

25.7

31.5

480 V

CT

1.4

2.8

3.9

4.5

5.9

7.6

12.3

14.9

19.9

25.7

Rated input voltage

Three-phase: 380 V-15% to 480 V+10%, 50/60 Hz±5%

Rated output voltage

Three-phase: 380 to 480 V (proportional to input voltage)

VT

2.1

4.1

5.4

6.9

8.8

11.1

17.5

23.0

31.0

38.0

Rated output current (A)

CT

1.8

3.4

4.8

5.5

7.2

9.2

14.8

18.0

24.0

31.0

Starting torque

200% at 0.5 Hz

70%: at

100% at 50 Hz

50 Hz

100%: at 50 Hz

Without resistor

Braking

50%: at 60 Hz

50%: at

50%: at 60 Hz

60 Hz

With resistor

150%

DC braking

Variable operating frequency, time, and braking force

kg

1.5

1.6

1.8

1.9

1.9

2.1

3.5

3.5

4.7

5.2

Weight

lb

3.3

3.5

4.0

4.2

4.2

4.6

7.7

7.7

10.4

11.5

MX2 Quick Start Guide Draft

5

MX2 Quick Start Guide

2 INSTALLATION

2.1 Wiring sizes and protection

Inverter rating

Wiring

Applicable equipment

(KW)

Inverter Model

Terminal

Tighttening

Fuse

VT

CT

Power Lines (mm2)

Signal Lines

screw

Toque (N/m)

(UL-rated, class J, 600 V)

0.2

0.1

3G3MX2-AB001

0.4

0.2

3G3MX2-AB002

AWG16 / 1.3 mm²

M4

1.0

10 A

0.55

0.4

3G3MX2-AB004

1.1

0.75

3G3MX2-AB007

AWG12 / 3.3 mm²

M4

1.4

15 A

2.2

1.5

3G3MX2-AB015

20 A

AWG10 / 5.3 mm²

M4

1.4

3.0

2.2

3G3MX2-AB022

30 A

0.2

0.1

3G3MX2-A2001

0.4

0.2

3G3MX2-A2002

10 A

AWG16 / 1.3 mm²

M4

1.0

0.75

0.4

3G3MX2-A2004

1.1

0.75

3G3MX2-A2007

15 A

2.2

1.5

3G3MX2-A2015

AWG14 / 2.1 mm²

M4

1.4

3.0

2.2

3G3MX2-A2022

AWG12 / 3.3 mm²

M4

1.4

20 A

5.5

3.7

3G3MX2-A2037

AWG10 / 5.3 mm²

M4

1.4

18 to 28 AWG

30 A

7.5

5.5

3G3MX2-A2055

0.14 to 0.75 mm²

AWG6 / 13 mm²

M5

3.0

11

7.5

3G3MX2-A2075

shielded wire

40 A

15

11

3G3MX2-A2110

AWG4 / 21 mm²

M6

3.9 to 5.1

60 A

18.5

15

3G3MX2-A2150

AWG2 / 34 mm²

M8

5.9 to 8.8

80 A

0.75

0.4

3G3MX2-A4004

1.5

0.75

3G3MX2-A4007

AWG16 / 1.3 mm²

M4

1.4

10 A

2.2

1.5

3G3MX2-A4015

3.0

2.2

3G3MX2-A4022

AWG14 / 2.1 mm²

M4

1.4

4.0

3.0

3G3MX2-A4030

5.5

4.0

3G3MX2-A4040

A

WG12 / 3.3 mm²

M4

1.4

15 A

7.5

5.5

3G3MX2-A4055

AWG10/ 5.3 mm²

M5

3.0

11

7.5

3G3MX2-A4075

20 A

15

11

3G3MX2-A4110

30 A

AWG6 / 13 mm²

M6

3.9 to 5.1

18.5

15

3G3MX2-A4150

40 A

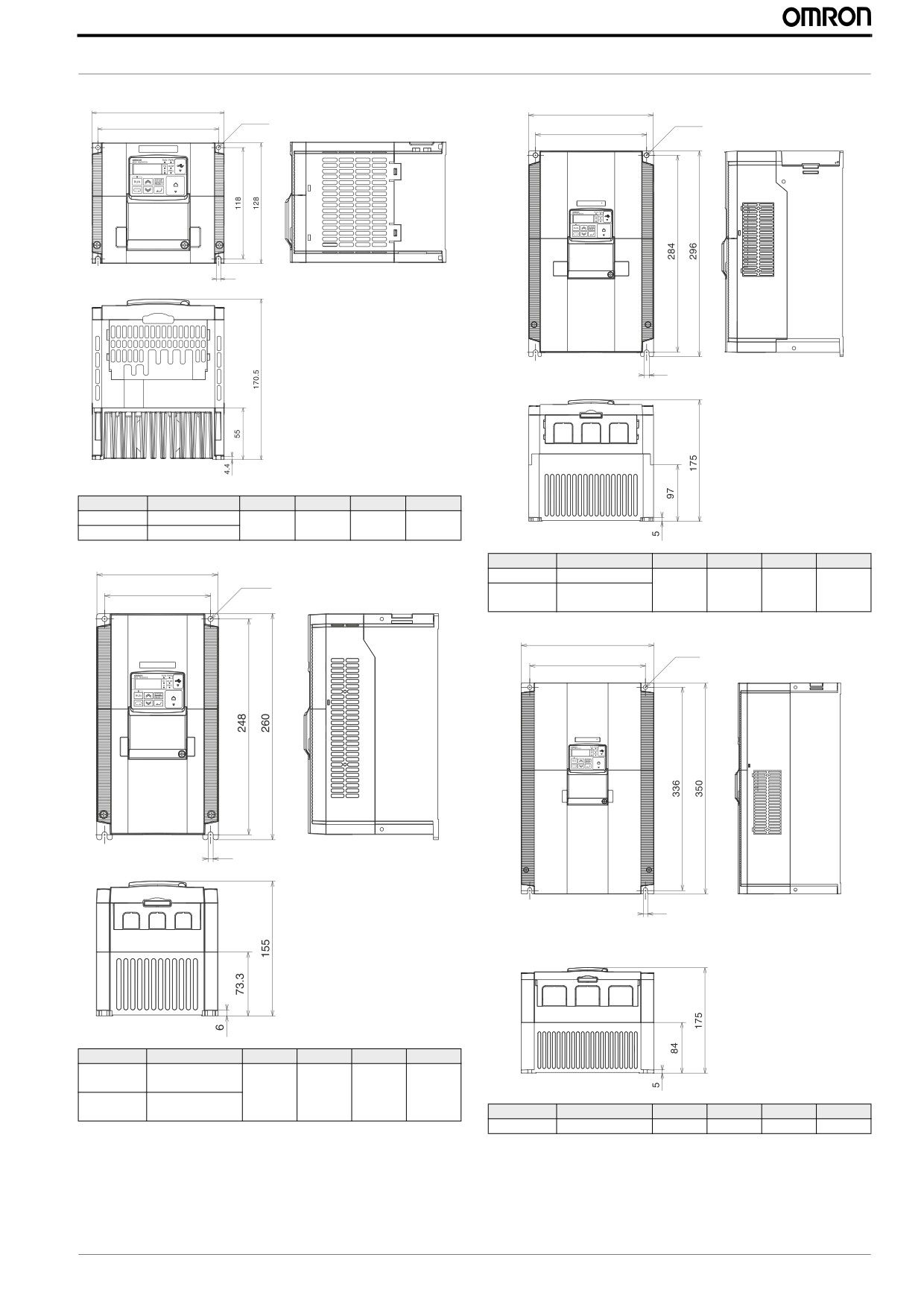

2.2 External dimensions for installation (IP20 & IP54)

68

108

Ø4.5

2-Ø4.5

56

96

8.8.8.8.

8.8.8.8.

5

5

Power

Type

W (mm) H (mm)

D (mm)

D1 (mm)

Power

Type

W(mm)

H (mm)

D (mm)

D1(mm)

3G3MX2-AB001

3G3MX2-AB007

109

13.5

1x 200V

3G3MX2-AB002

1x 200 V

3G3MX2-AB015

170.5

55

3G3MX2-AB004

122.5

27

3G3MX2-AB022

3G3MX2-A2001

68

128

3G3MX2-A2015

109

13.5

3x 200 V

170.5

55

3G3MX2-A2002

3G3MX2-A2022

3x 200 V

108

128

3G3MX2-A2004

122.5

27

3G3MX2-A4004

143.5

28

3G3MX2-A2007

145.5

50

3G3MX2-A4007

3x 400V

3G3MX2-A4015

170.5

55

3G3MX2-A4022

3G3MX2-A4030

6

MX2 Quick Start Guide Draft

INSTALLATION

140

180

2-Ø4.5

2-Ø7

128

160

8.8.8.8.

8.8.8.8.

5

7

Power

Type

W(mm)

H (mm)

D (mm)

D1(mm)

3x 200 V

3G3MX2-A2037

140

128

170,5

55

3x 400 V

3G3MX2-A4040

Power

Type

W(mm)

H (mm)

D (mm)

D1(mm)

140

3x 200 V

3G3MX2-A2110

2-Ø6

122

3G3MX2-A4110

180

296

175

97

3x 400 V

3G3MX2-A4150

220

2-Ø7

192

8.8.8.8.

8.8.8.8.

6

7

Power

Type

W(mm)

H (mm)

D (mm)

D1(mm)

3G3MX2-A2055

3x 200 V

3G3MX2-A2075

140

260

155

73.3

3G3MX2-A4055

3x 400 V

3G3MX2-A4075

Power

Type

W(mm)

H (mm)

D (mm)

D1(mm)

3 x 200 V

3G3MX2-A2150

220

350

175

84

MX2 Quick Start Guide Draft

7

MX2 Quick Start Guide

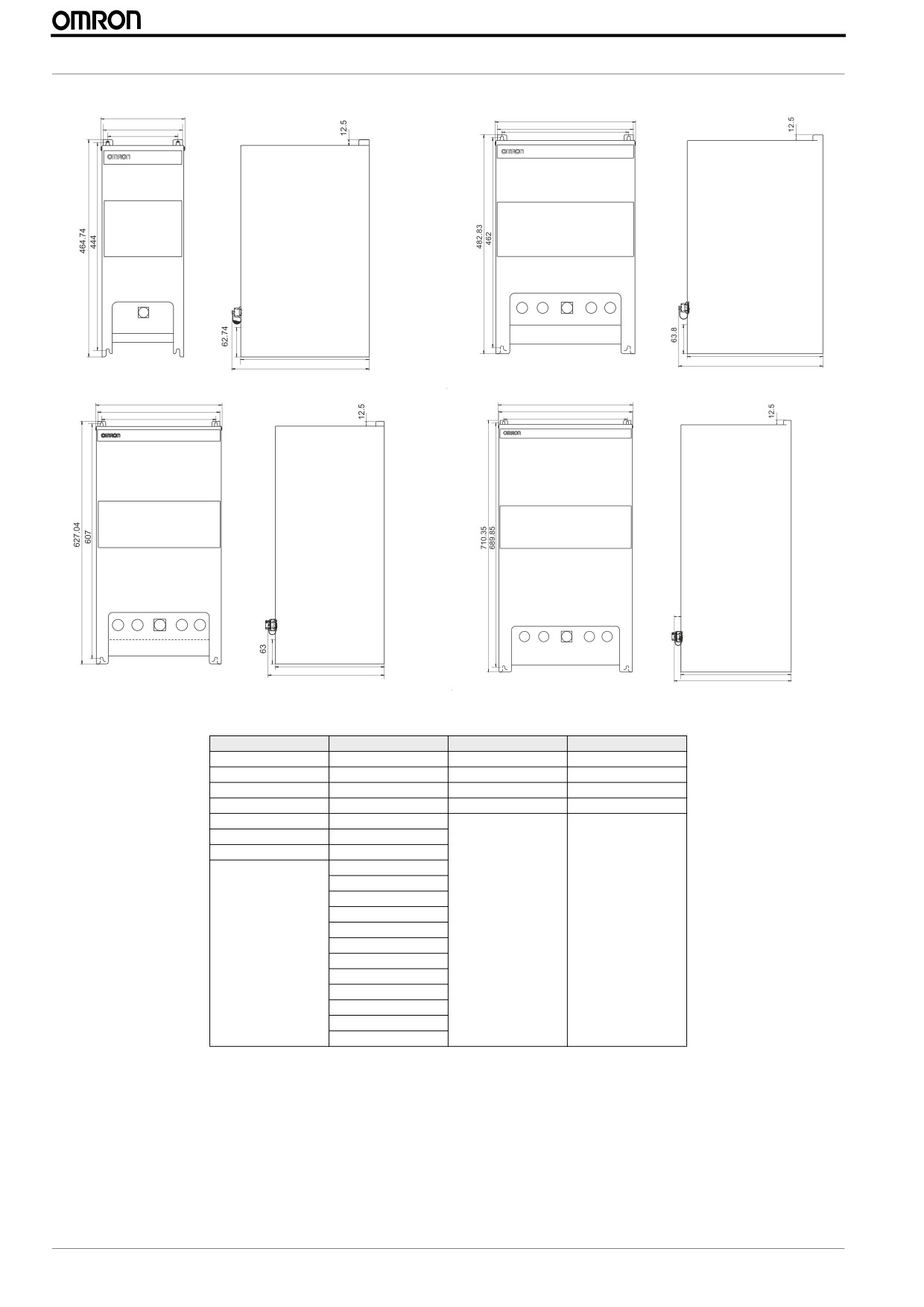

IP54

179.5

Figure 1

309.5

Figure 2

169.5

299.5

279.5

150

298.9

274

292.7

317.7

325

378.8

315

Figure 3

376.2

Figure 4

295

349

18.7

281

320.53

299.5

334.7

Figure 1

Figure 2

Figure 3

Figure 4

3G3MX2-DB001-E

3G3MX2-DB001-EC

3G3MX2-D2055-EC

3G3MX2-D2110-EC

3G3MX2-DB002-E

3G3MX2-DB002-EC

3G3MX2-D2075-EC

3G3MX2-D2150-EC

3G3MX2-DB004-E

3G3MX2-DB004-EC

3G3MX2-D4055-EC

3G3MX2-D4110-EC

3G3MX2-D2001-E

3G3MX2-DB007-EC

3G3MX2-D4075-EC

3G3MX2-D4150-EC

3G3MX2-D2002-E

3G3MX2-DB015-EC

3G3MX2-D2004-E

3G3MX2-DB022-EC

3G3MX2-D2007-E

3G3MX2-D2001-EC

3G3MX2-D2002-EC

3G3MX2-D2004-EC

3G3MX2-D2007-EC

3G3MX2-D2015-EC

3G3MX2-D2022-EC

-

3G3MX2-D2037-EC

3G3MX2-D4004-EC

3G3MX2-D4007-EC

3G3MX2-D4015-EC

3G3MX2-D4022-EC

3G3MX2-D4030-EC

3G3MX2-D4040-EC

8

MX2 Quick Start Guide Draft

INSTALLATION

Chassis ground of

mounting plate

Chassis ground of

EMC filter

Power input to

EMC filter

DIN rail for

mounting options

Bracket with

EMC filter

Fuse for

cooling fan

MX2 inverter

Cooling fan

Dust filter

Wiring acces hole

Mounting plate

Air outlet

Front cover

Window for MX2

inverter display

Lock for

front cover

USB connector

(mini-B)

Panel hole for accessory

2.3 Installation Environment clearance

100 mm or more

Provide sufficient

space so that the top

Air flow

and bottom wiring

ducts, etc. will not

obstruct the flows of

cooling air.

Wall

50 mm or more

50 mm or more

100 mm or more

Side by side installation is possible but ambient temperature should not exceed 40ºC and for some cases carrier frequency and

output current should be derated. Please refer to MX2 user’s manuals for details.

MX2 Quick Start Guide Draft

9

MX2 Quick Start Guide

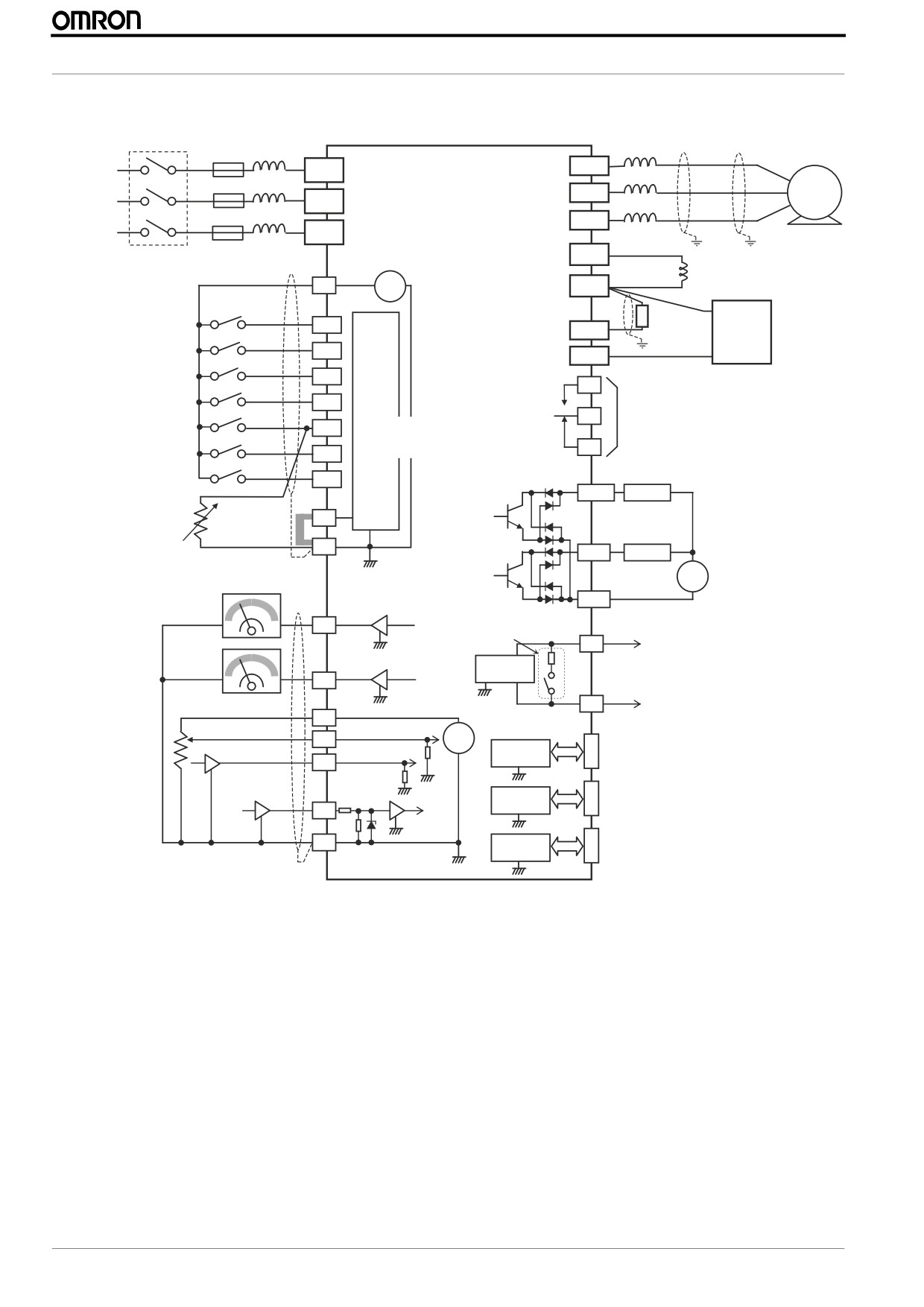

2.4 Wiring overview

Shielded motor cable

Breaker, MCCB

AC Reactor

Output

to minimize emitted EMC

or GFI,

dV/dt

Groudn both ends

Fuses

R

U (T1)

( L1 )

Motor

Power source,

MX2

3-phase or

V (T2)

S

1-phase, per

( L2 )

inverter model

W (T3)

T

N(L3)

PD/+1

DC reactor

Intelligent inputs,

24V

(optional)

7 terminals

P24

+ -

P/+

Forward

NOTE:

Brake

Braking

For the wiring of intelligent

1

RB

resistor

unit

I/O and analog inputs,

Reverse

(optional)

(optional)

be sure to use twisted

2

N/-

pair / shielded cable.

External Trip

Input

Attach the shielded wire

3/GS1

circuits

AL1

for each signal to its

Reset

Relay contacts,

respective common

4/GS2

type 1 Form C

terminal at the inverter

Multi-speed 1

AL0

end only.

[5] configurable as

5/PTC

Input impedance of

discrete input or

Multi-speed 2

each intelligent input is

thermistor input

AL2

6

4.7 kΩ

Open collector output

Jog

Output circuit

RUN

7/EB

11/EDM

Load

Thermistor

Short bar

PLC

(Source type)

Freq. arrival signal

L

12

Load

GND for logic inputs

L

+

-

Freq. Meter

CM2

Termination resistor (200 Ω)

Common for logic outputs

EO

(Change by slide switch)

L

SP

Volt. Meter

RS485

Serial communication port

transceiver

(RS485/ModBus)

AM

transceiver

L

L

SN

Analog reference

10 VDC

H

0~10VDC

+

O

RJ45 port

Apprx.10 Ω

-

RS485

4~20mA

(Optional operator port)

OI

transceiver

Pulse train input

Apprx.100 Ω

L

USB (mini-B) port

24 VDC 32 kHz max.

L

USB

(PC communication port)

transceiver

EA

USB power: Self power

L

L

L

Option port

Option port connector

GND for analog signals

controller

L

L

10

MX2 Quick Start Guide Draft

INSTALLATION

2.5 Power wiring

Terminal name

Purpose

Details

R, S, T

Main circuit, power supply

Single phase 200-240V (Connect to L1 and N terminals)

(L1, L2, L3)

Three phase 200-240V

Three phase 380-480V

U, V, W

Motor output

Three phase motor connection (IM, PM)

(T1, T2, T3)

+1, +

DC reactor

Remove the link and install DC reactor for improvement of harmonics level and

power factor

RB

Extrenal brake resistor

An external braking resistor is connected.

+, -

Regeneration braking unit

For connection of external regeneration braking unit

G

Earth

Earthing terminal.

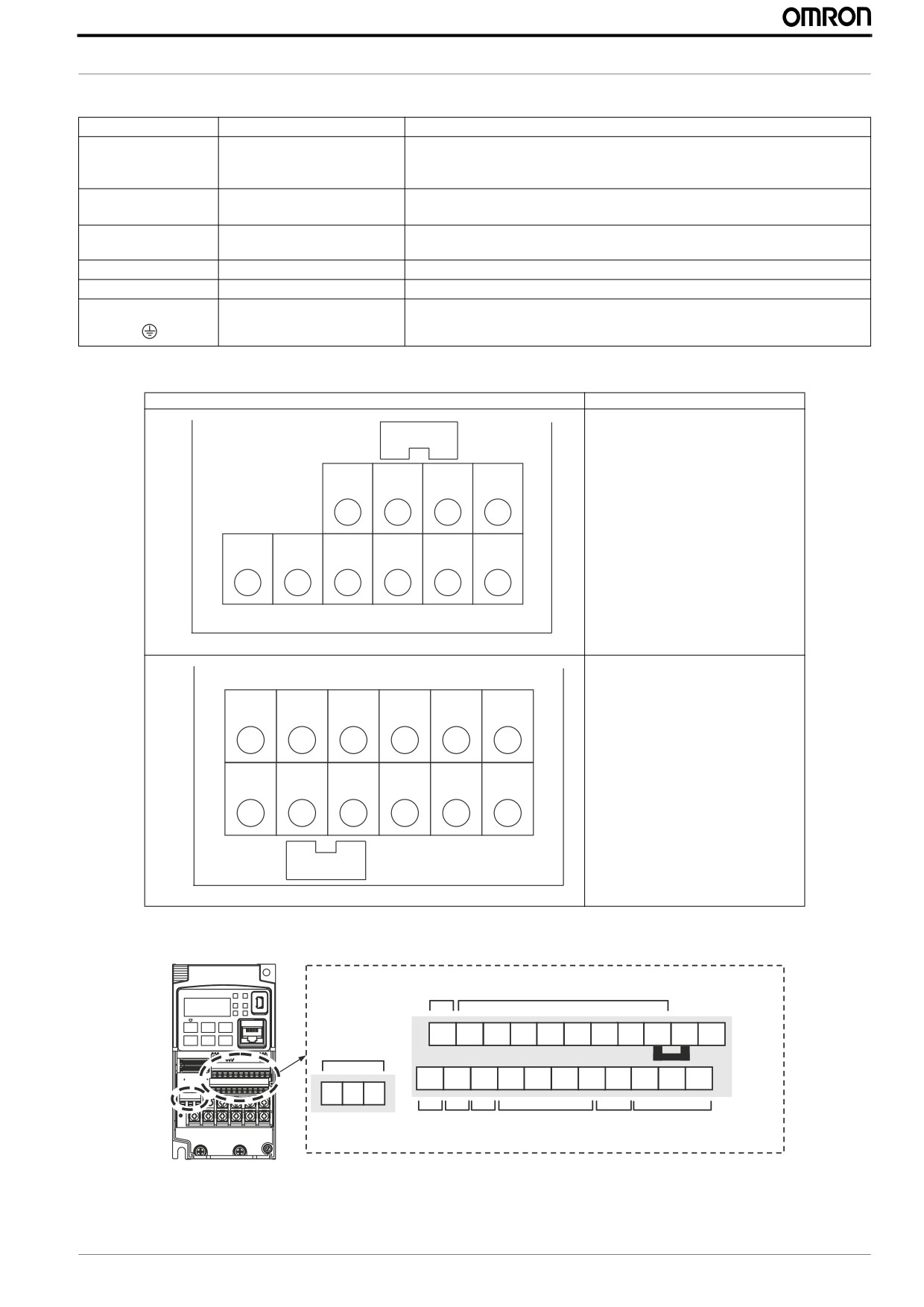

Terminals arrangment

Applicable models

3G3MX2-AB001 to AB022

WR OLQN

5HPRYH IRU '&

3G3MX2-A2001 to A2037

UHDFWRU FRQQHFWLRQ

3G3MX2-A4004 to A4040

5%

5 /

6 /

7 /

8 7

9 7

: 7

3G3MX2-A2040 to A2150

3G3MX2-A4055 to A4150

5 /

6 /

7 /

8 7

9 7

: 7

5%

WR OLQN

5HPRYH IRU '&

UHDFWRU FRQQHFWLRQ

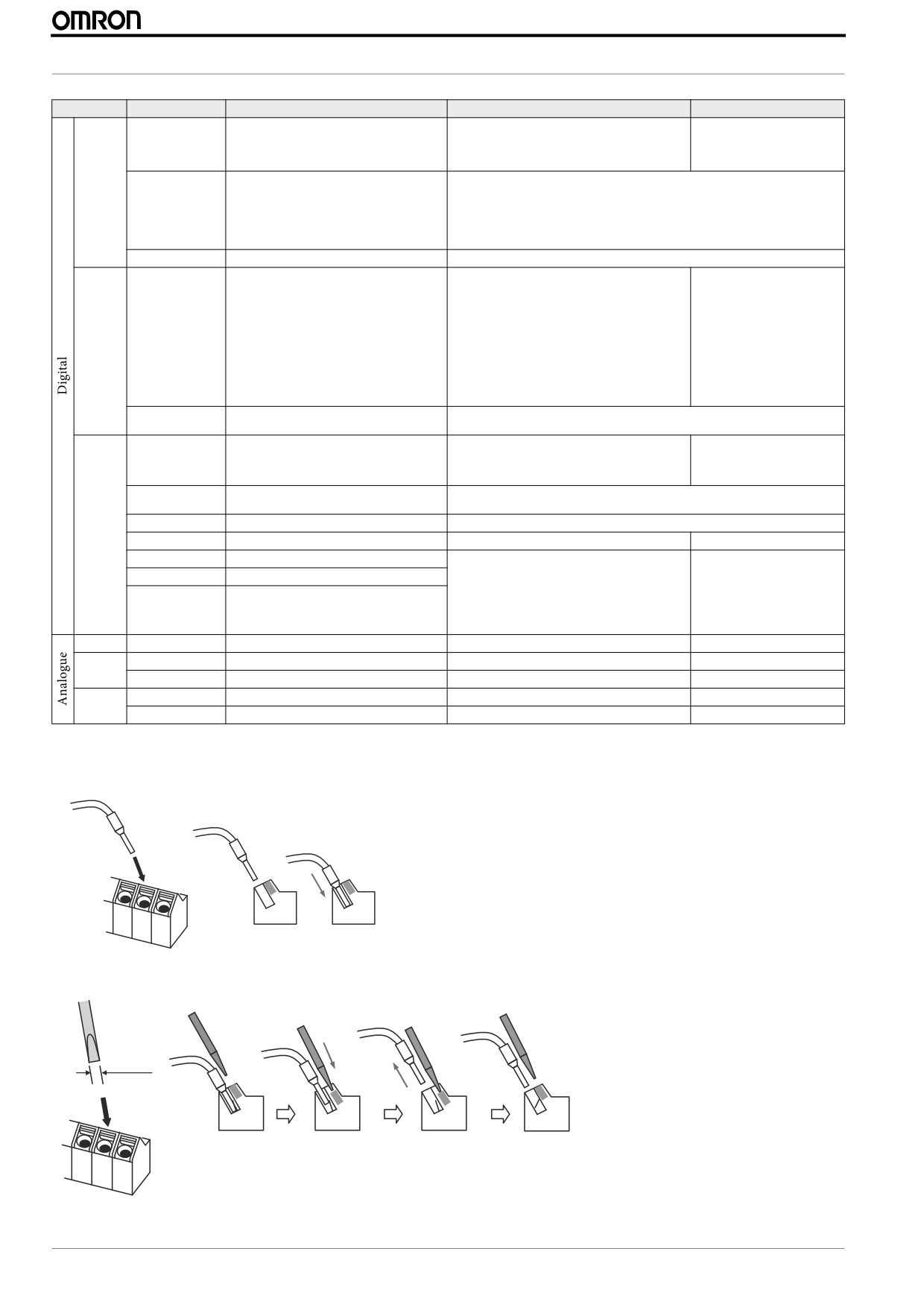

2.6 Control wiring

RS485

comm.

Logic inputs

Relay

SN

7

6

5

4

3

2

1

L

PLC

P24

contacts

Short bar

SP EO

EA

H

O

OI

L

AM CM2 12

11

AL2 AL1 AL0

RS485

Pulse

Pulse

Analog

Analog

Logic

Train

Train

output

comm.

input

output

onput

input

MX2 Quick Start Guide Draft

11

MX2 Quick Start Guide

Type

Terminal Name

Purpose

Details

Electrical specifications

P24

+24 V for logic inputs

24VDC power supply for the DI

Max 100mA including DI (5mA

When source logic is selected, it becomes the common

each)

point of input

(do not short to terminal L)

PLC

Intelligent input common

This terminal is used as the common terminal of the DI.

Power

For internal supply (and voltage-free contacts):

supply

Short between P24 and PLC: Sink logic (the current will flow from the MX2 input to the

output)

Short between CM1 and PLC: Source logic (the current will flow from the output to the

MX2 input)

L (upper row)

GND for logic inputs

Sum of input [1]~[7] currents (return)

1

Discrete logic inputs

It is possible to allocate any of the digital multifunction

ON voltage: 18V min

(Terminal [3],[4],[5] and [7] have dual function)

inputs to this terminals.

OFF voltage: 3V max

2

When safety function is enable by hardware dip-switch

Max.voltage: 27 VDC

multifunction setting 77:GS1 amd 78:GS2 are compul-

3/GS1

Load current: 5mA at 24V

sory for terminals 3 and 4 and functionality change

based on ISO13849-1

4/GS2

For PTC connect the motor thermistor between termi-

Input

5/PTC

nals 5 and L and assign 19:PTC on parameter C005.

Inverter will trip when thermistor exceed 3kOhm.

6

For pulse train input B set 85:EB in C007 parameter.

Max freq for this terminal is 2kHz.

7/EB

EA

Pulse train input A

32 kHz max.

Common is [L]

11/EDM

Discrete logic outputs [11]

Any multifunction output signal can be set to this ter-

50mA max. ON state current,

(Terminal [11] has dual function. Selected by

minals.

27 VDC max. OFF voltage

hardware switch)

In case the EDM is selected, the functionality is based

on ISO13849-1

12

Discrete logic outputs [12]

50 mA max. ON state current, 27 VDC max. OFF state voltage

Common is CM2

CM2

GND for logic output

100 mA: [11], [12] current return

Output

EO

Pulse train output

10 VDC 32 kHz maximum

2mA maximum

AL0

Relay common contact

Any multifunction output signal can be set to this ter-

250 VAC 2.5 A(R load) max.

minals.

250 VAC 0.2 A (I load,P.F.=0.4)

AL1

Relay contact, normally open

100 VAC 10 mA min.

AL2

Relay contact, normally closed

30 VDC 3.0 A(R load) max.

30 VDC 0.7 A(I load, P.F.=0.4)

5 VDC 100 mA min

Output AM

Analog voltage output

0~10 VDC

1 mA maximum

OI

Analog current input

4 to 19.6 mA range, 20 mA nominal,

input impedance 100 W

Input

O

Analog voltage input

0 to 9.8 VDC range, 10 VDC nominal,

input impedance 10 KW

+10 V analog reference

10 VDC nominal, 10 mA max

Power

H

supply L (bottom row)

GND for analog signals

Sum of [OI], [O], and [H] currents (return)

2.7 Screwless terminals connection

To connect cable, just push the terminal into position

To release cable, press the orange tab with small screwdriver and remove the cable

2.5 mm

Push the screwdriver

Pull out the cable

Release the

screwdriver

12

MX2 Quick Start Guide Draft

INSTALLATION

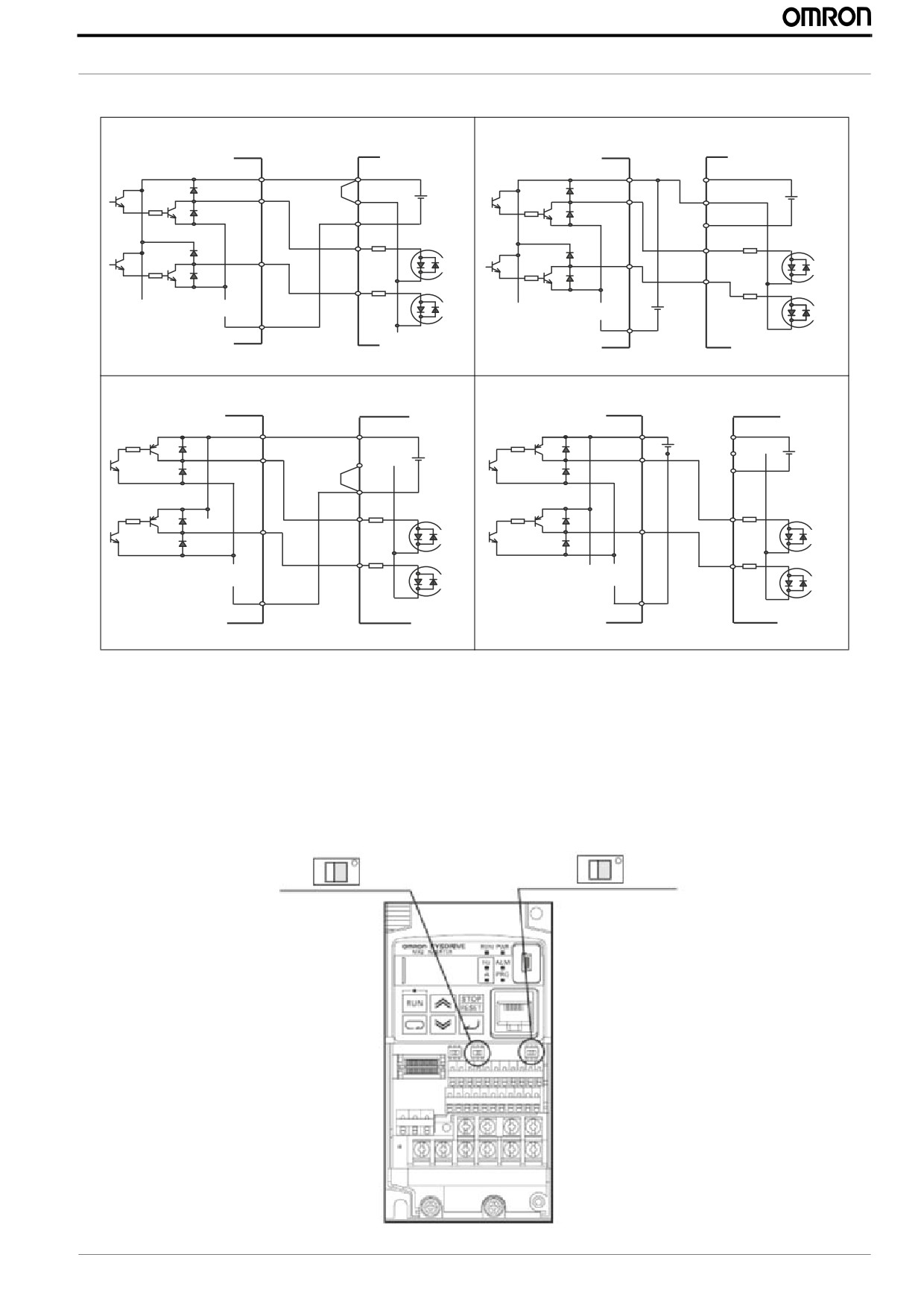

2.8 Digital inputs SINK/SOURCE (NPN/PNP) settings

Sinking internal supply

Sinking external supply

(for NPN outputs)

(for NPN outputs

+V

P24

+V

P24

Short-circuit

PLC

PLC

bar

24 V DC

24 V DC

L

L

1

1

7

7

COM

DC24V

COM

Output unit etc.

Output unit etc.

Inverter

Inverter

Sourcing internal supply

Sourcing external supply

(for PNP outputs)

(for PNP outputs

COM

P24

P24

COM

24 V DC PLC

Short-circuit

PLC

24 V DC

L

24 V DC

bar

L

1

1

7

7

0V

0V

Output unit etc.

Output unit etc.

Inverter

Inverter

2.9 Safe stop disable function

MX2 inverter incorporates a SAFE STOP function at hardware level according with EN60204-1 stop category 0. It is designed to

meet the requirements of the ISO13849-1, PL=d and IEC61508 SIL 2 only in a system in which EDM signal is monitored by an

“external device monitor”. Two redundant inputs are required (3/GS1 and 4/GS2). The function is purely hardware based. but to

activate it you should set below switches to ON. This will fix the configuration of multi-function inputs 3 (C003=77) and 4

(C004=78) and also for the multi-function output 11 (C021=62).

When the switches are set to OFF the multi-function input and output the configuration is set to No function selection

6DIHW\ IXQFWLRQ VHOHFWRU VZLWFK

('0 IXQFWLRQ VHOHFWRU VZLWFK

2))

21

2))

21

QRUPDO

('0

MX2 Quick Start Guide Draft

13

MX2 Quick Start Guide

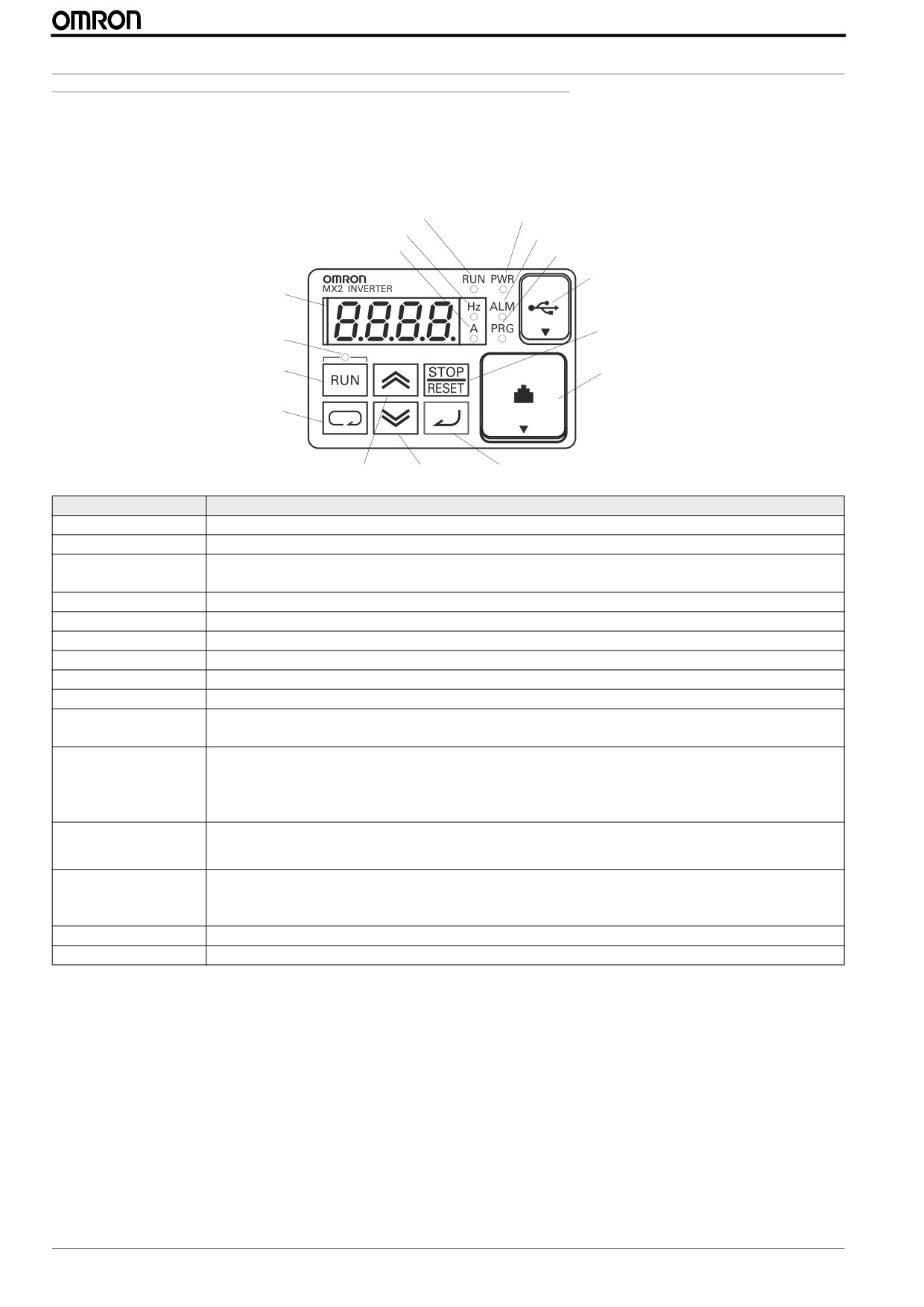

3 PROGRAMMING MX2

3.1 Digital operator

The display is used in programming the inverter's parameters, as well as monitoring specific parameter values during operation

(4) RUN LED

(1) POWER LED

(5) Monitor LED [Hz]

(2) ALARM LED

(6) Monitor LED [A]

(3) Program LED

(15) USB connector

(8) 7-seg LED

(7) Run command LED

(10) Stop/reset key

(9) RUN key

(16) RJ45 connector

(11) CYCLE key

(12) Up key

(13) Down key

(14) Set Key

Items

Contents

(1) POWER LED

Turns ON (Green) while the inverter is powered up.

(2) ALARM LED

Turns ON (Red) when the inverter trips.

(3) Program LED

Turns ON (Green) when the display shows changeable parameter.

Blinks when there is a mismatch in setting.

(4) RUN LED

Turns ON (Green) when the inverter is driving the motor.

(5) Monitor LED [Hz]

Turns ON (Green) when the displayed data is frequency related.

(6) Monitor LED [A]

Turns ON (Green) when the displayed data is current related.

(7) Run command LED Turns ON (Green) when a Run command is set to the operator. (Run key is effective.)

(8) 7-seg LED

Shows each parameter, monitors etc.

(9) Run key

Makes inverter run.

(10) Stop/reset key

Makes inverter decelerates to a stop.

Reset the inverter when it is in trip situation

(11) CYCLE key

Go to the top of next function group, when a function mode is shown

Cancel the setting and return to the function code, when a data is shown

Moves the cursor to a digit left, when it is in digit-to-digit setting mode

Pressing for 1 second leads to display data of , regardless of current display.

(12) Up key

Increase or decrease the data.

Pressing the both keys at the same time gives you the digit-to-digit edit.

(13) Down key

(14) SET key

Go to the data display mode when a function code is shown

Stores the data and go back to show the function code, when data is shown.

Moves the cursor to a digit right, when it is in digit-to-digit display mode

(15) USB connector

Connect USB connector (mini-B) for using PC communication

(16) RJ45 connector

Connect RJ45 jack for remote operator

14

MX2 Quick Start Guide Draft

PROGRAMMING MX2

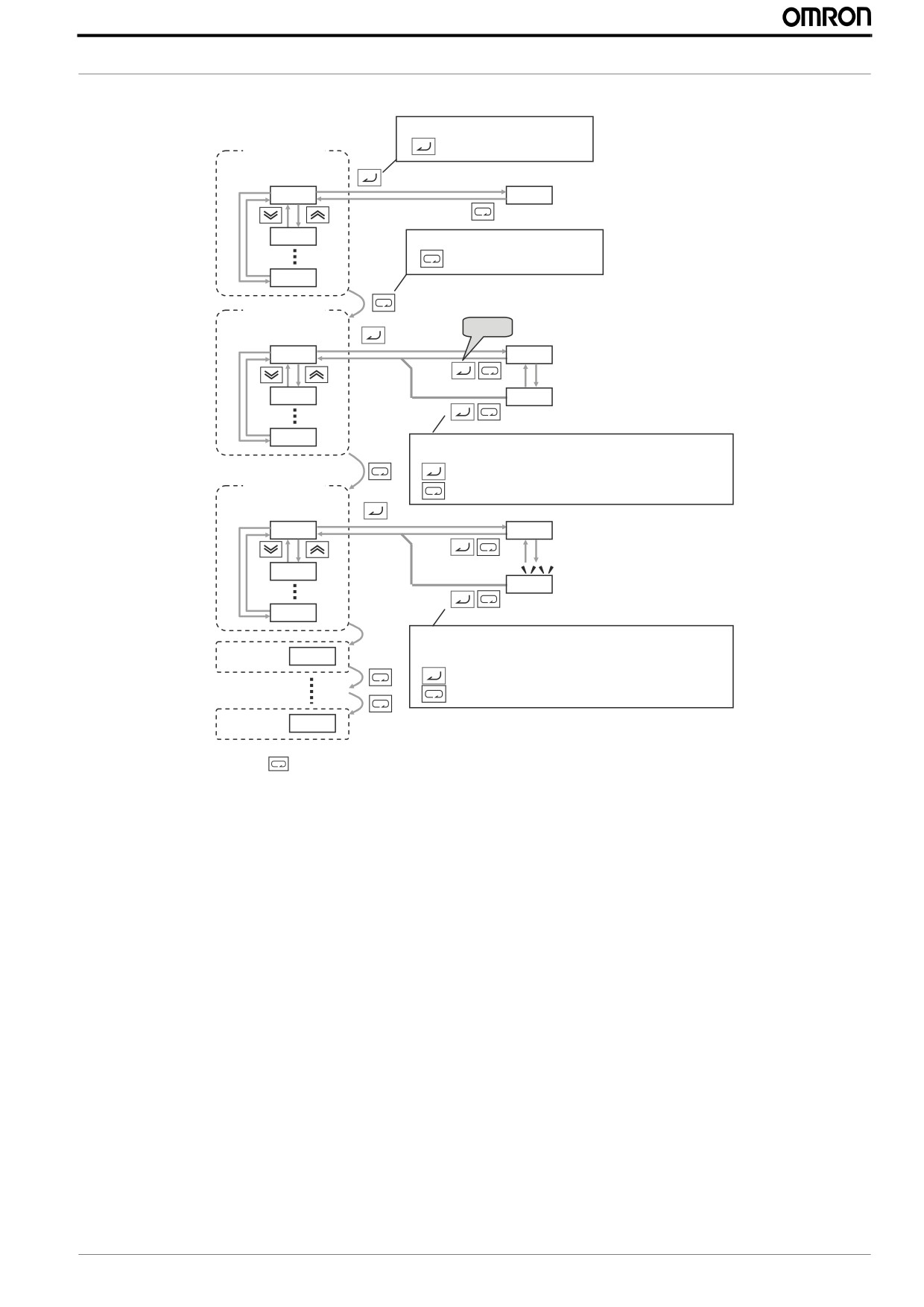

3.2 Keypad navigation

Func. code display

: Moves to data display

Group "d"

Func. code display

D001

0.00

D002

Func. code display

: Jumps to the next group

d104

Group "F"

Func. code display

Save

F001

50.00

F002

50.01

F004

Data display (F001 to F*03)

Data does not blink because of real time synchronizing

: Saves the data in EEPROM and returns to func. code display

Group "A"

: Returns to func. code display without saving data.

Func. code display

A001

00

A002

01

A165

Data display

When data is changed, the display starts blinking, which means that

Group "b"

b001

new data has not been activated yet.

: Saves the data in EEPROM and returns to func. code display

: Cancels the data change and returns to func. code display.

Group "U"

U001

Pressing

for a few seconds will return to the initial display

Pressing at the same time the up and down key in function code or data display will enable the single-digit edit mode that allows

a faster navigation, refer to the manual for more details.

3.3 Initialization

You can restore all inverter parameters to the original factory (default) settings according to area of use. After initializing the

inverter, use the power up test in Chapter 2 to get the motor running again. If operation mode (std. or high frequency) mode is

changed, inverter must be initialized to activate new mode. To initialize the inverter, follow the steps below.

• Select initialization mode in b084.

00 Initialization disable

01 Clears trip history

02 Initializes all Parameters

03 Clears Trip history and initializes all parameters

04 Clears Trip history and initializes all parameters and drive programming

• If =, or , select initialization target data in .

00 All parameters

01 All parameters except I/O configuration

02 Only parameters register in Uxxx

03 All parameter except the ones registered in Uxxx and b037

• Set

MX2 Quick Start Guide Draft

15

MX2 Quick Start Guide

The following display appears for a few seconds, and initialization is completed with d001 displayed

Display during initialization

5 HC

Initialization of trip history

Initialization

5 00

Initialization for area A

mode

5 01

Initialization for area B

The left digit rotates during initialization

d001

Blinking alternately

1-C

HD mode

Operation

mode after

1-V

ND mode

initialization

H-1

High frequency mode

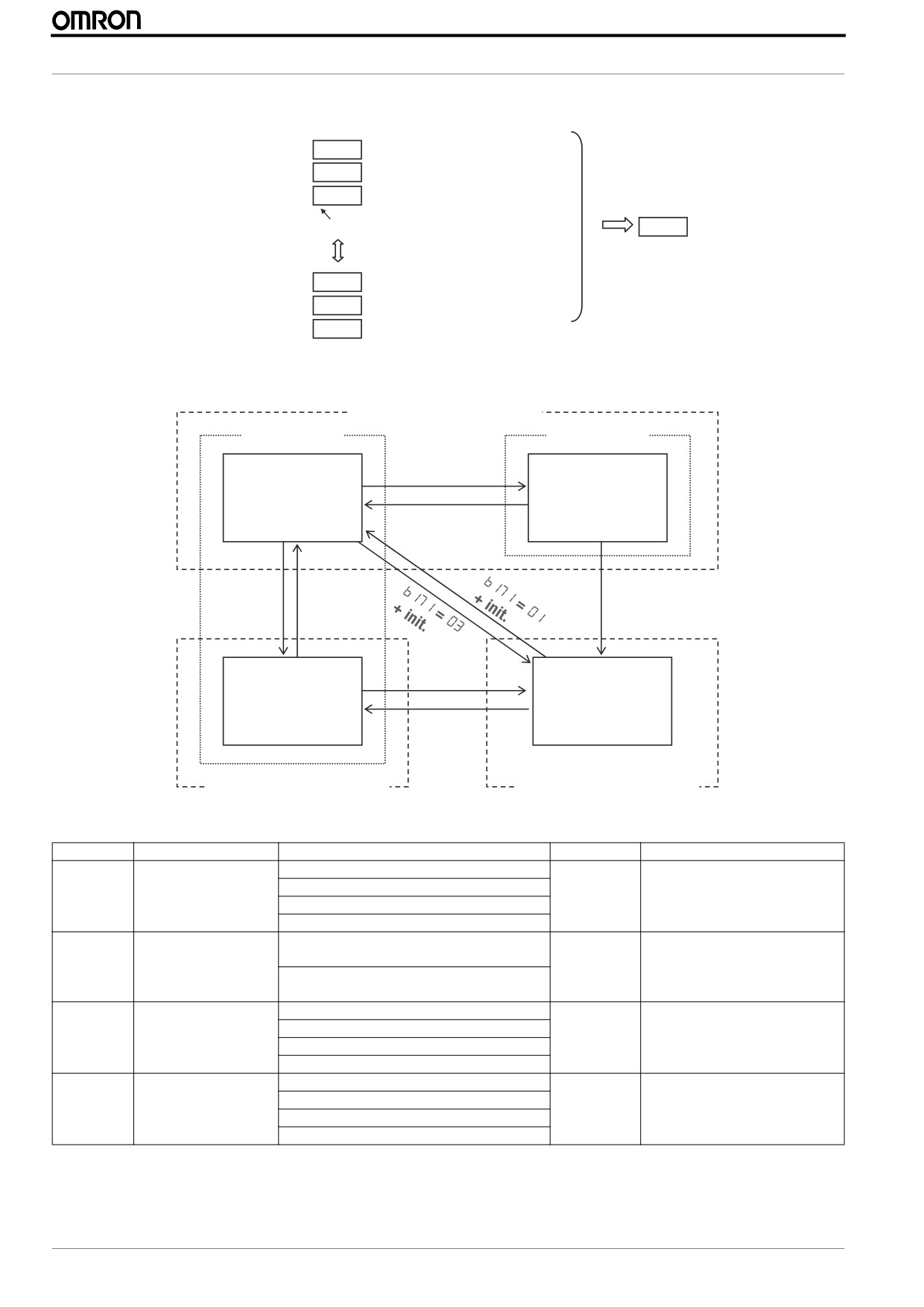

3.4 Inverter modes

Normal mode (㹼400 Hz)

HD mode

ND mode

HD mode

b049 = 01

ND mode

b049: 00

b049: 01

d060:

1-C

b049 = 00

d060:

1-v

b171 = 02

b171 = 01

b171 = 03

+ init.

+ init.

+ init.

b171 = 03

High freq. mode

+ init.

Permanent magnet

mode

d060: H-1

d060: P

b171 = 02

+ init.

High freq. (㹼1000 Hz)

Permanent magnet mode

Display code

Function name

Setting range/content

Initial value

Remarks

V/f characteristic curve

00: Constant torque

0

For the second motor use parame-

01: Reduced torque

ter A244

A044

02: Free V/F

03: Sensorless Vector Control

Dual rating selection

00: Constant torque

00

Some parameters default and

150% overload during 60s

ranges depends off this setting.

b049

01: V

ariable torque

Refer to below table for details

120% overload during 60s

Inverter mode selection

00: No function

00

To enable the new mode is neces-

01: Standard Induction Motor

sary to initialize the inverter

b171

02: High Frequency Induction Motor

03: Permanent Magnet Motor

Inverter mode monitor

IM-CT (Induction motor constant torque)

-

Displays the current inverter mode

IM-VT(Induction motor variable torque)

use this one to check configuration

d060

Hi-IM (High frequency induction motor)

as b171 returns to 0 after initialize

PM (Permanent magnet motor)

Neither the A044 or the b049 needs a initialization but remember to initialize the drive setting b180=01 when the inverter mode

is changed on b171.

16

MX2 Quick Start Guide Draft

PROGRAMMING MX2

This table shows the parameters that change with the dual rating selectiong is modified

Name

Func.

HD

ND

code

Range

initial data

Range

initial data

V/f characteristic curve

A044

00: Const. torque

00: Const. tq.

00: Const. torque

00: Const. tq.

01: Reduced torque

01: Reduced tq.

02: Free V/F

02: Free V/F

03: SLV

DC braking force for deceleration

A054

0 to 100 (%)

50 (%)

0 to 70 %

50 (%)

DC braking force at start

A057

0 to 100 (%)

0 (%)

0 to 70 %

0 (%)

Carrier frequency during DC braking A059

2.0 to 15.0(kHz)

5.0(kHz)

2.0 to 10.0(kHz)

2.0(kHz)

Overload restriction level

b022

(0.20 to 2.00)

1.50 x Rated current (0.20 to 1.50)

1.20 x Rated current

Overload restriction level 2

b025

x Rated current (A)

(A)

x Rated current (A)

(A)

Carrier frequency

b083

2.0 to 15.0(kHz)

5.0(kHz)

2.0 to 10.0(kHz)

2.0(kHz)

Motor capacity

H003

0.1 to 15(kW)

Depends on type

0.2 to 18.5(kW)

One size up than

HD

3.5 Basic settings

After selecting the inverter mode follow next steps for a basic operation of the inverter

•

Select frequency reference source on parameter A001

Parameter nº

Parameter Name

Details

00 Potentiometer of ext. operator

01 Control terminals

02 Digital operator (F001)

03 ModBus Network

A001

Frequency source

04 Option

06 Pulse train input

07 Via Drive programming

10 Calculate function output

•

Select Run command source on parameter A002

Parameter nº

Parameter Name

Details

01 Control terminals

02 Run key on keypad or digital operator

A002

Run command source

03 Modbus network input

04 Option

•

Adjust the stopping method by b091 and the acceleration/deceleration ramps on parameters F002 and F003

Parameter

Parameter Name

Details

00: Deceleration to stop

b091

Stop mode selection

01: Free Run

F002

Acceleration time (1)

0.01 to 3600.00

F003

Deceleration time(1)

0.01 to 3600.00

•

Set the motor base frequency and AVR voltage of the motors in parameters A003 and A082

Parameter

Parameter Name

Details

A003

Base Frequency

30.0 to maximum frequency in A004

200V: 200 to 240V

A082

AVR voltage select

400V: 380 to 480V

•

Set the motor data: rated current (b012), rated power (H003) and number of poles (H004)

Parameter

Parameter Name

Details

b012

Level of electronic thermal

20% to 100% of inverter rated current

H003

Motor capacity

0.1 to 18.5KW

H004

Motor poles settings

2 to 48 poles

•

When working in sensorless vector control perform motor auto tuning by parameter H001 (see next section for details)

MX2 Quick Start Guide Draft

17

MX2 Quick Start Guide

At this point the inverter is ready to run the motor for the first time, but first review this check-list:

• Verify the power LED is ON. If not, check the power connections.

• Verify the PRG LED is OFF. If it is ON, review the instructions above.

• Make sure the motor is disconnected from any mechanical load.

• Make sure that you have a frequency reference checking the content of F001 and the Hz Led on operator

• Now give the RUN command from the selected source. The RUN LED will turn ON.

• The motor should start turning.

• Remove the RUN command or press the STOP key to stop the motor rotation.

3.6 Auto tuning (SLV Mode)

The MX2 inverter has auto-tuning function to get suitable motor control performance by measuring the motor constants auto-

matically. Auto-tuning is effective only for sensorless vector control. Basically two modes are available the static and the rotative

one:

• Static is less accurate but it could be used in situations where motor rotation could damage the mechanics. For this mode nei-

ther the I0 (no-load current) or the J (inertia) are calculated.

• Rotative auto-tuning moves the motor following a special operation pattern to find the motor characteristics. However, the

torque during auto-tuning is not sufficient so is recommended to detach the mechanical system and don’t use for example

with vertical loads.

The Auto-tuning mode is selected by parameter H001 and after it finish succefully is necessary to to select the auto-tuning

parameters by parameter H002.

Parameter

Parameter Name

Description

00: Disable

H001

Auto-tuning selection

01: Enabled with motor stop

02: Enabled with motor rotation

00: Standard motor

H002

Motor constant selection

02: Auto tuned data

For a correct auto-tuning calculation please take into account following recommendations before starting:

• Use only a motor of the same size or one size lower than the inverter.

• Be sure to disable the DC braking setting (A051=00)

• Be sure to deactivate ATR digital input (52: Enable torque cmd. input)

• Motor rotates up to 80% of base frequency, check if it’s a problem for the application.

• Motor should not be driven by any other external force.

• All the brakes should be released

• Be sure that physical limtis of the machine will not be reach

• Even for none-rotative auto-tuning there is a risk that motor moves slightly

After checking the above points and setting parameter H001 procced with the activation of the Run command from the source

selected on A002 and the auto-tuning will start. Please check the diagram on next page for detailed information of all the steps.

After the tuning the H001 returns to “00” status and the motor characteristics are transferred to those parameter, remember to

set H002 to use them.

Parameter

Parameter Name

Description

H030

Motor constant R1

0.001 to 65.535 Ohms

H031

Motor constant R2

0.001 to 65.535 Ohms

H032

Motor constant L

0.01 to 655.35 mH

H033

Motor constant I0

0.01 to 655.35 A

H034

Motor constant J

0.001 to 9999 kgm2

Note: In case rotary tuning is not possible or autotuning results in very high No Load current (H033) (this is possible with small

motors), please use this formula to calculate theoretical value:

H033 = Inom * sin (arccos(cos phi)).

18

MX2 Quick Start Guide Draft

PROGRAMMING MX2

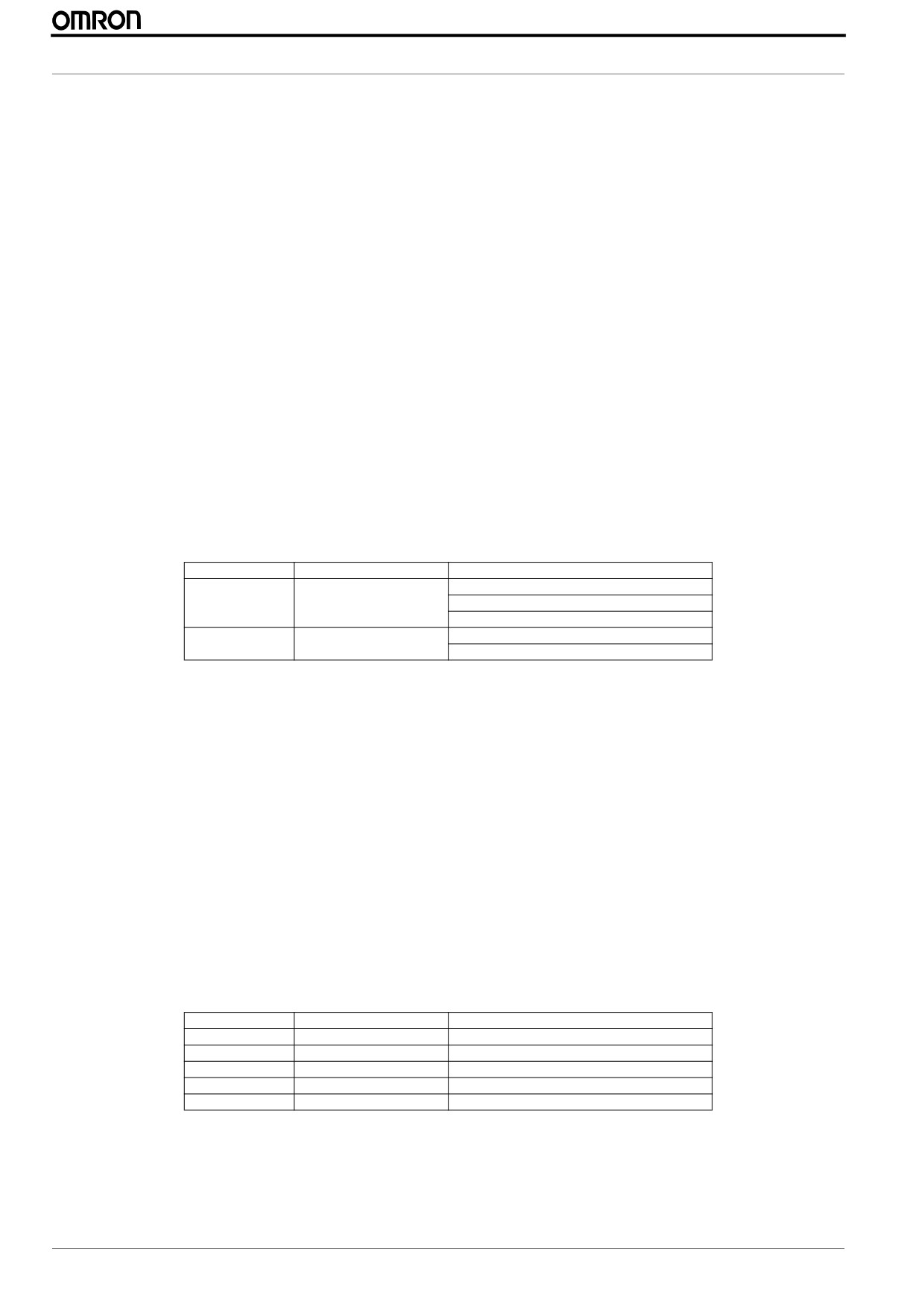

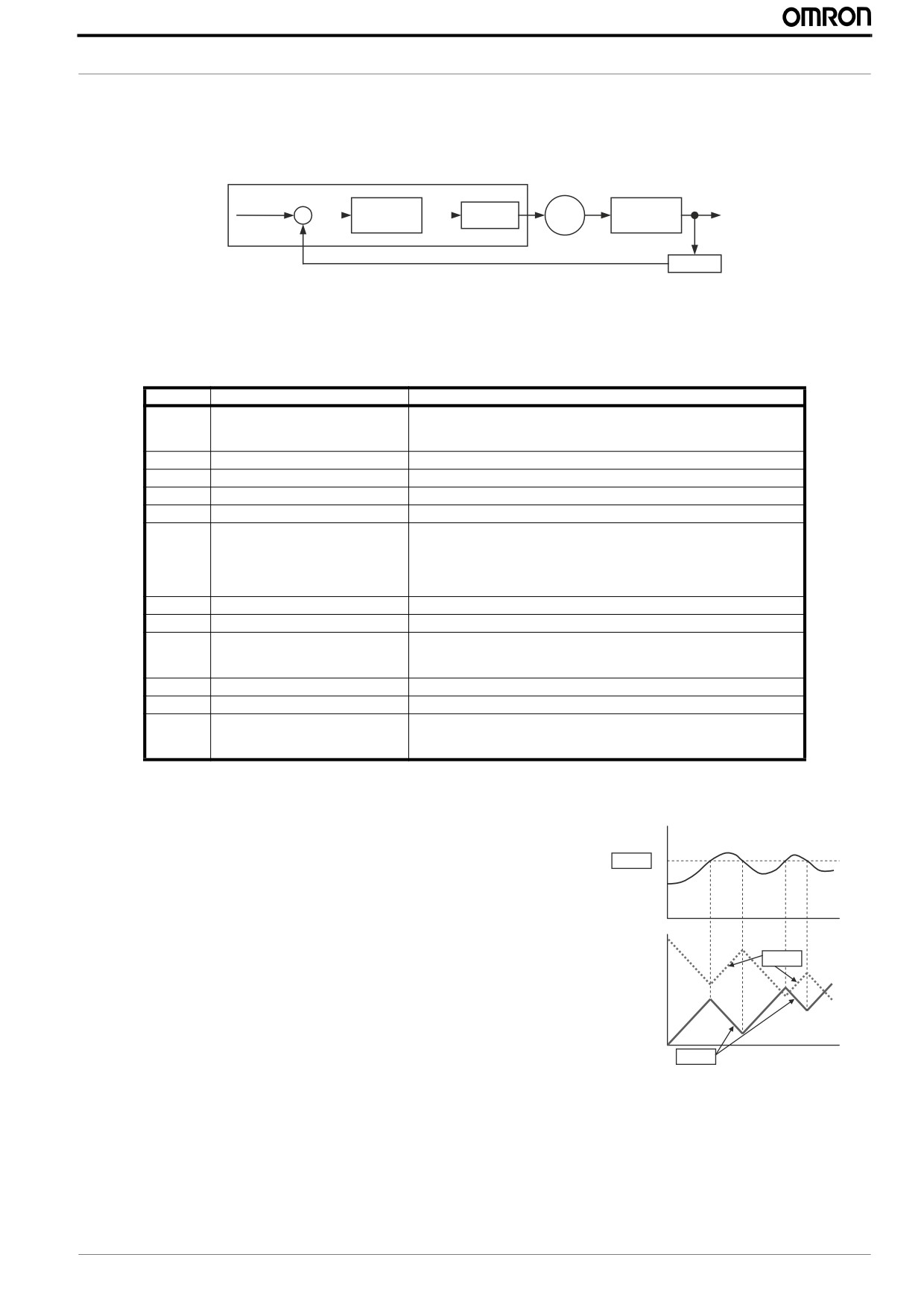

Next diagram shows the auto-tuning procedure with motor rotation

Step 1: Set motor size and

Step 2:Set base freq. and

Step 3: Enable auto-tuning

motor poles

AVR voltage

H001

02

H003

Motor size

A003

Base freq.

H004

Motor poles

A082

AVR voltage

Result is displayed

Auto-tuning starts

Step 4: Start the inverter

according to RUN

cmd source

___o

Completed

___9

Failed

Step 5: Clear display by

STOP key

When RUN cmd. is given, the motor runs according to

following steps.

(1) 1st AC excitation (no rotation)

(2) 2nd AC excitation (no rotation)

(3) 1st DC excitation (no rotation )

Step 6: Activate motor

(4) V/f operation (80% of base freq.)

constant by H002

(Note 1)

(5) SLV operation (X % of base freq.)

H002

02

(6) 2nd DC excitation (no rotation)

(7) Displays the result.

A fine tuning could be achived setting parameter H005 that adjust the motor speed response. If the motor vibrates at constant

speed then you should reduce the H005 setting, if on the contrary the response of the motor is not enough you could increase the

value.

The H005 acts as a global gain response but also is possible to adjust the motor response at certain areas adjusting the motor

parameters separately.

• The R1 parameter is adjusting the voltage applied at low speed, below 15-20Hz

• No load current I0 is used for adjusting the voltage above this 15-20Hz

• Finally R2 value is used to adjust the slip of the motor

No-load

V

current

R1

R2

15/20 Hz

Hz

Speed

MX2 Quick Start Guide Draft

19

MX2 Quick Start Guide

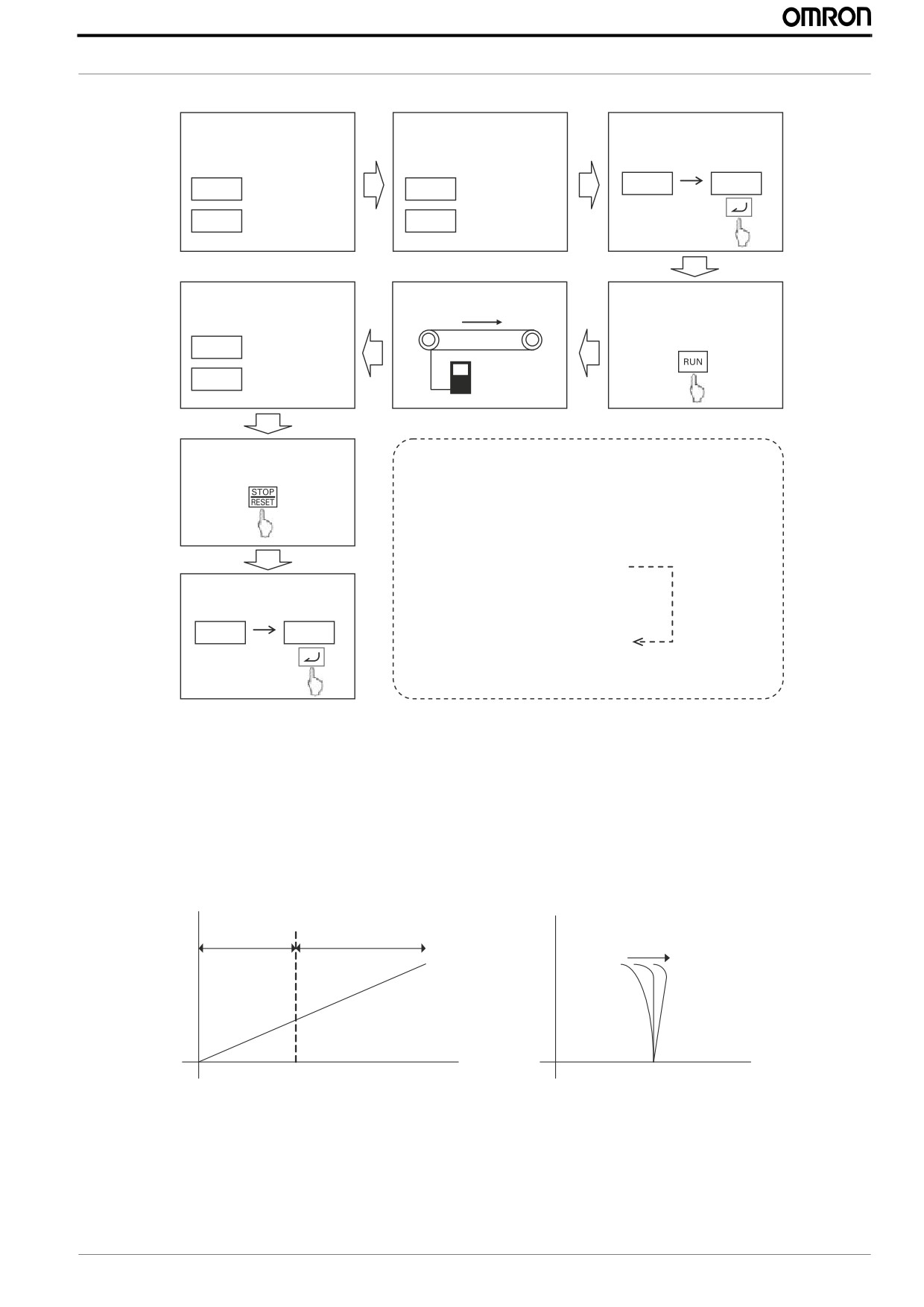

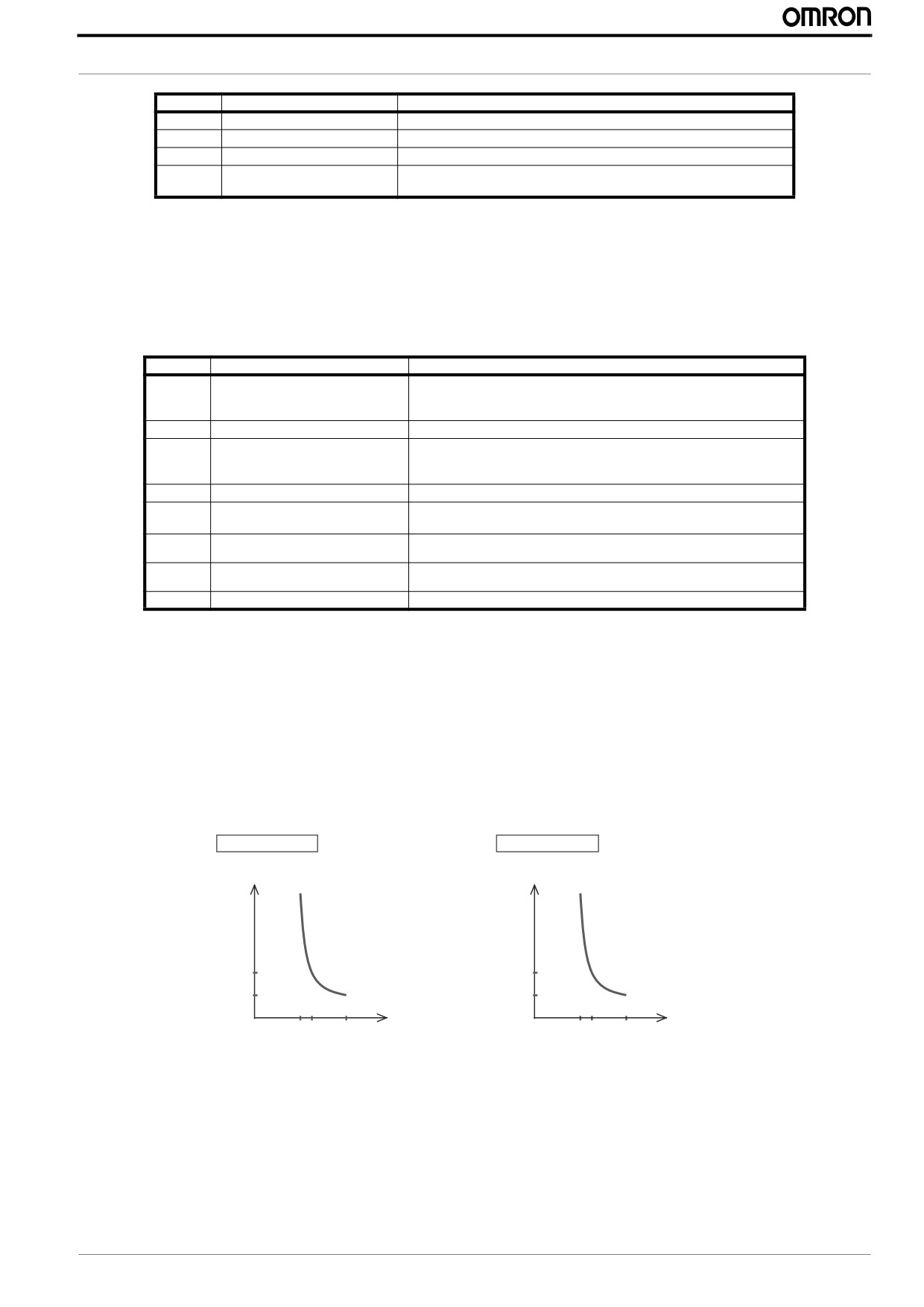

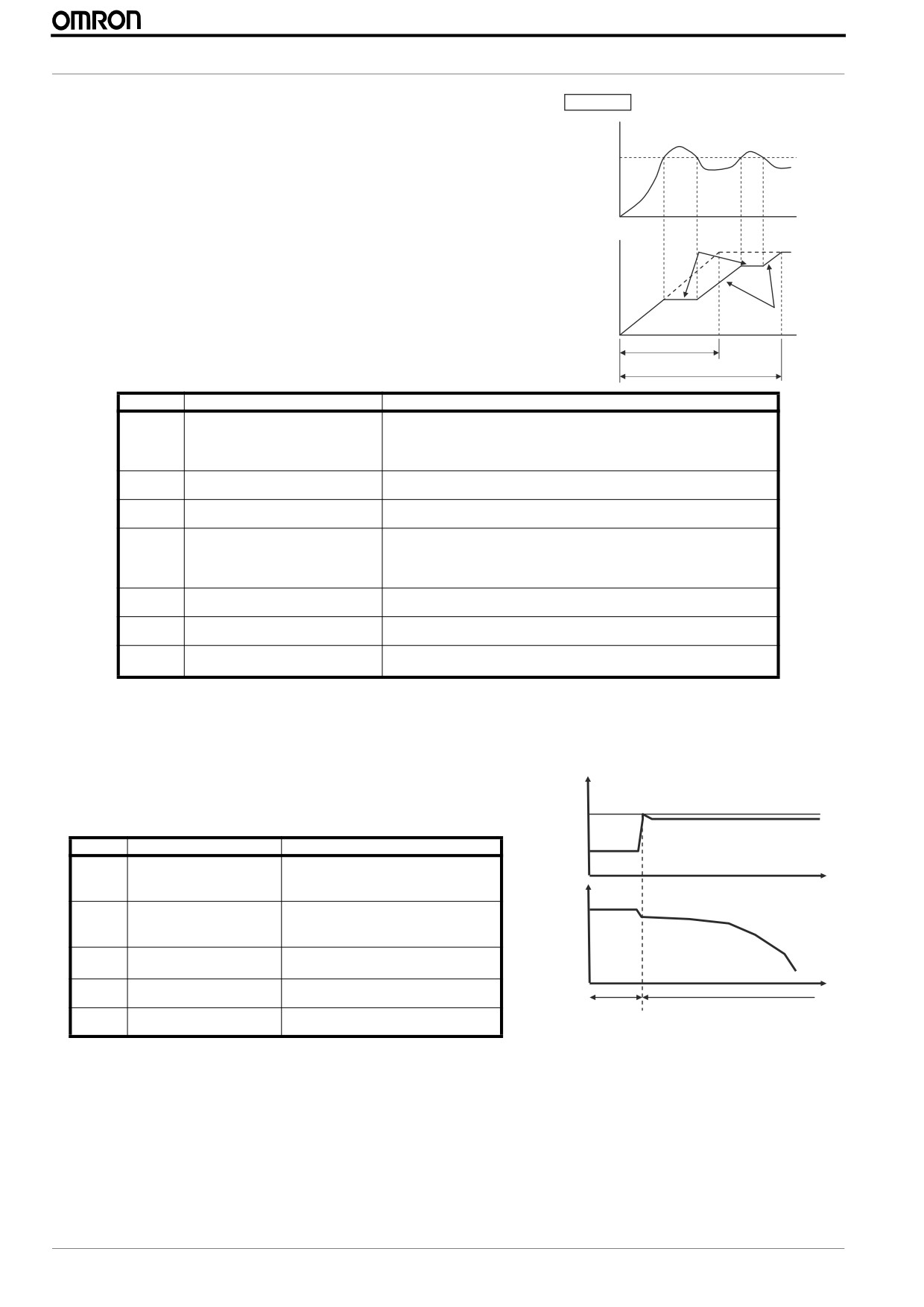

3.7 Ramps adjustment

The basic frequency (speed) profile is defined by parameters con-

Output

tained in the "F" Group as shown to the right. The set running fre-

frequency

F002

F003

quency is in Hz, but acceleration and deceleration are specified in

the time duration of the ramp (from zero to maximum frequency,

A004

or from maximum frequency to zero).

Acceleration 1 and Deceleration 1 are the standard default accel

F001

and decel values for the main profile. Accel and decel values for an

alternative profile are specified by using parameters through

.

b082

Acceleration and deceleration can be set via Drive programming as

well via parameter P031

0

t

Actual decel. time

Actual accel. time

Parameter

Parameter Name

Description

A004

Maximum frequency

30.0 to 400.0Hz

b082

Start frequency

0.01 to 9.99Hz

F001

Output frequency setting

0.00 to 400.00Hz

F002

Acceleration time(1)

0.01 to 3600.00s

F003

Deceleration time(1)

0.01 to 3600.00s

Accel/Decel setting

00: Via operator

P031

source selection

01: Via Drive Programming

Standard acceleration and deceleration is linear. The inverter CPU can

Output

frequency

Accel. curve selection

also calculate an S-curve acceleration or deceleration curve as shown.

Target

This profile is useful for favoring the load characteristics in particular

freq.

S-curve

applications. Even if the shape of the ramps change the time keeps

A097 = 01

being the same one set in F002/F003

Linear

A097 = 00

Curve settings for acceleration and deceleration are indepenently

selected. To enable the S-curve, use function A097 (acceleration) and

t

0

A098 (deceleration).

Acceleration period

Parameter

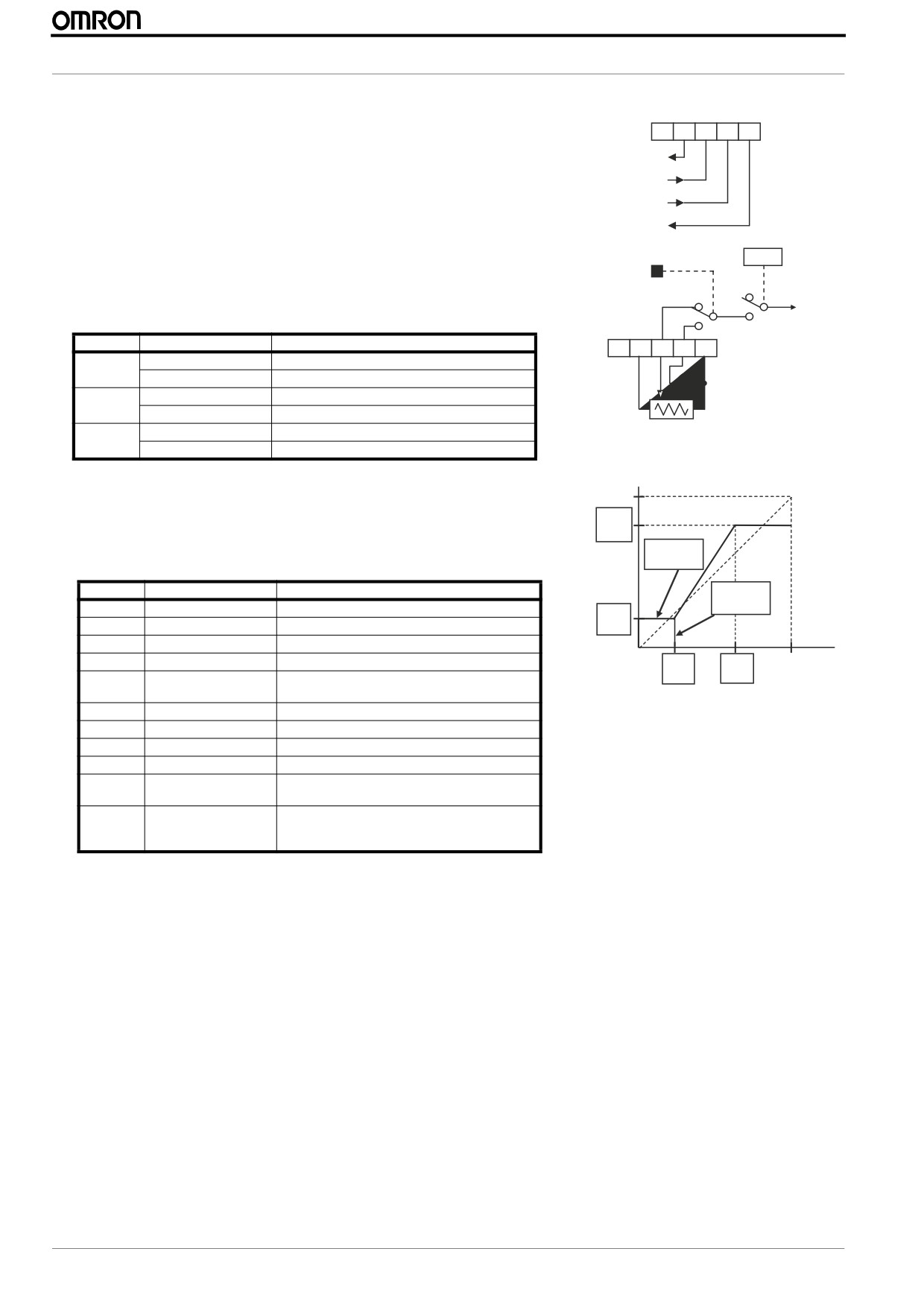

Parameter Name

Description

Acceleration curve selection

00: Linear curve

A097

01: S-curve

02: U-curve

Deceleration curve selection

A098

03: Inverse U-curve

04: EL-S curve

A131

Acceleration curve constant

Range is 01 to 10.

A132

Deceleration curve constant

Range is 01 to 10.

A150

Curvature of EL-S-curve at

Range is 0 to 50%

the start of acceleration

A151

Curvature of EL-S-curve at

Range is 0 to 50%

the end of acceleration

A152

Curvature of EL-S-curve at

Range is 0 to 50%

the start of deceleration

A153

Curvature of EL-S-curve at

Range is 0 to 50%

the end of deceleration

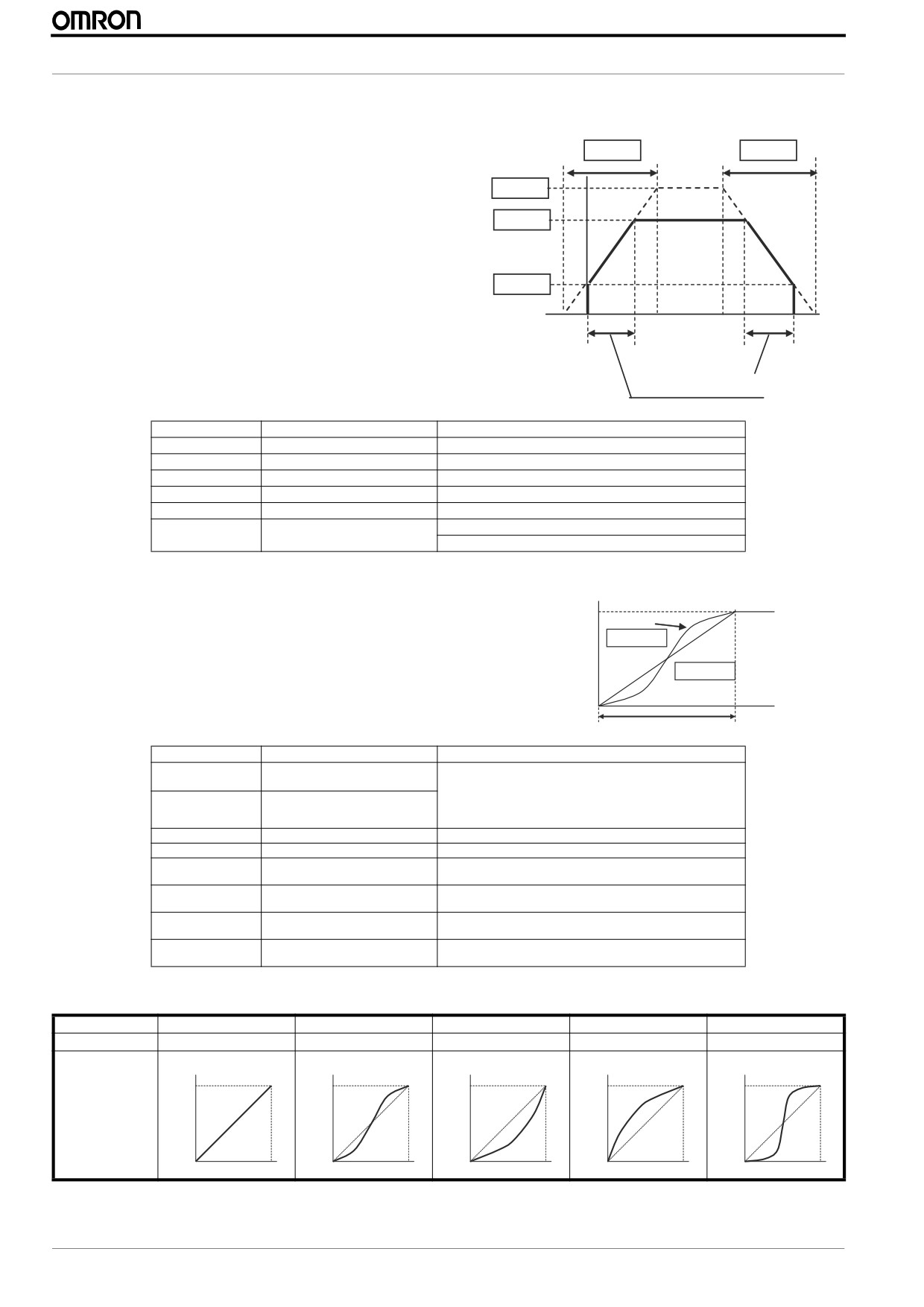

This table shows the different acceleration shapes

Setting

00

01

02

03

04

Curve

Linear

S-curve

U-curve

Inverse U-curve

EL S-curve

A097

Freq.

Freq.

Freq.

Freq.

Freq.

(Accel. pattern)

A098

(Decel. pattern)

t

t

t

t

t

20

MX2 Quick Start Guide Draft

PROGRAMMING MX2

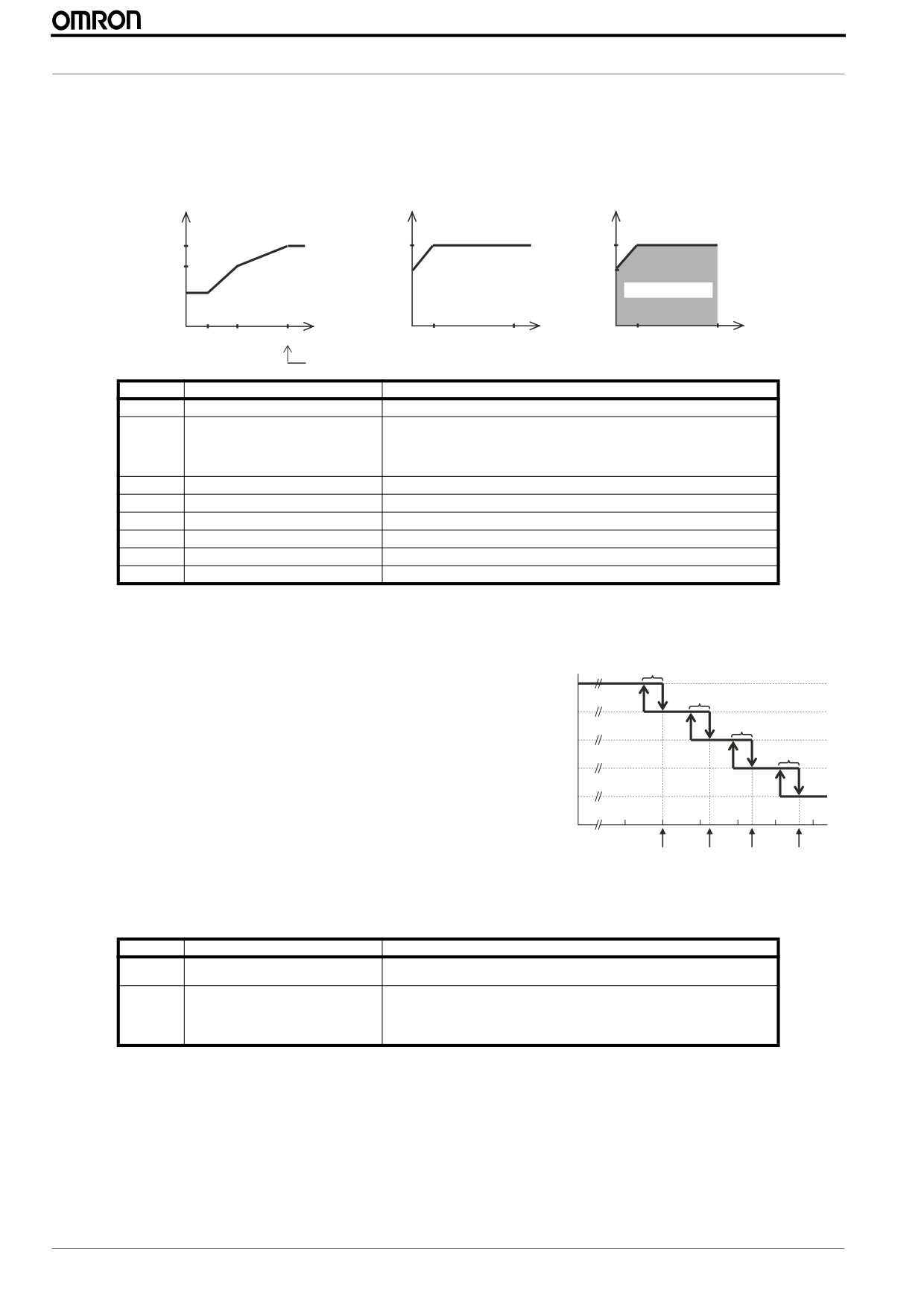

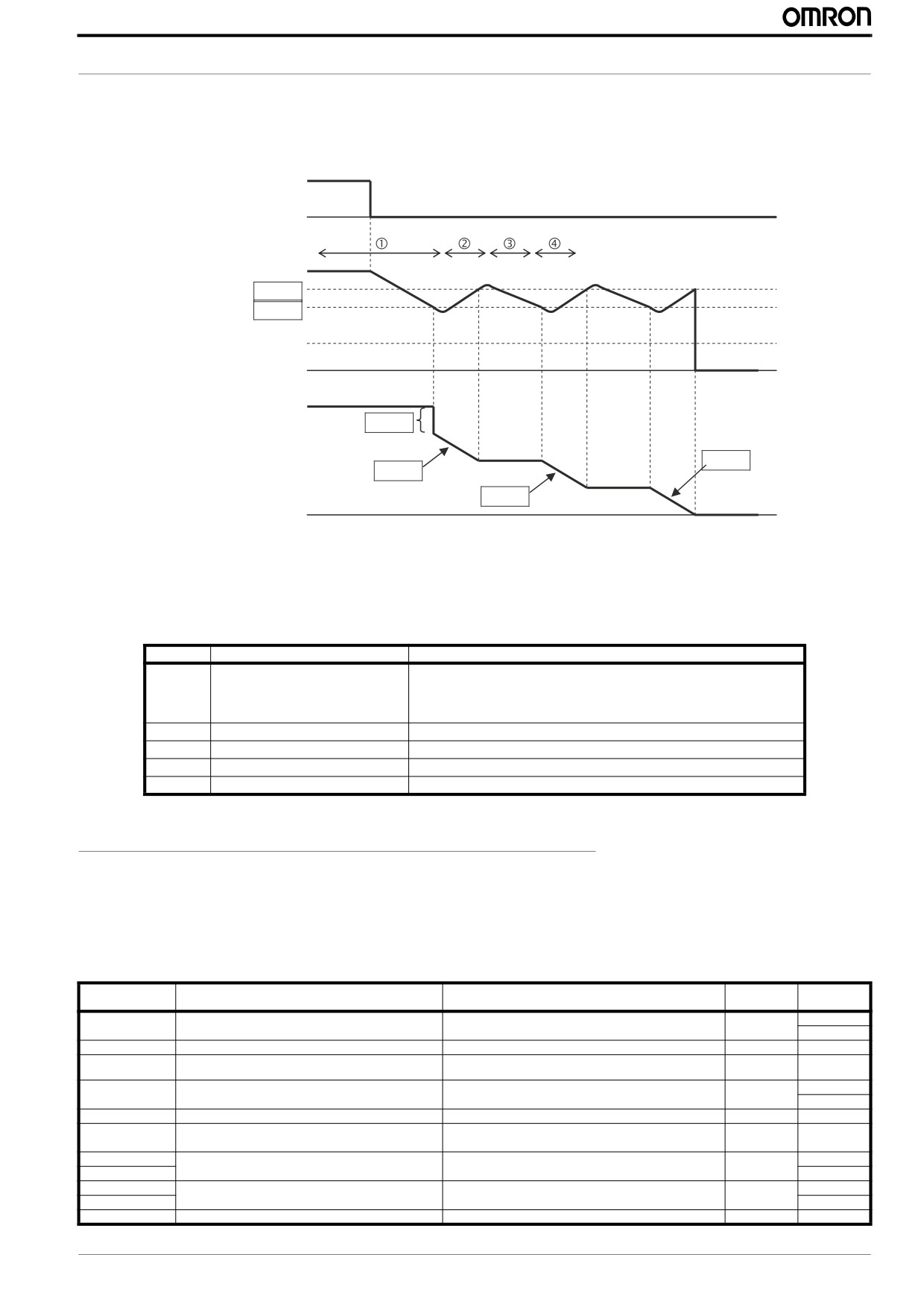

3.8 DC Braking

The DC braking feature can provide additional stopping torque during deceleration or before acceleration and is particulary use-

ful at low speeds when normal deceleration torque is minimal. This function injects a DC voltage into the motor windings which

generates a DC current that force the motor to stop.

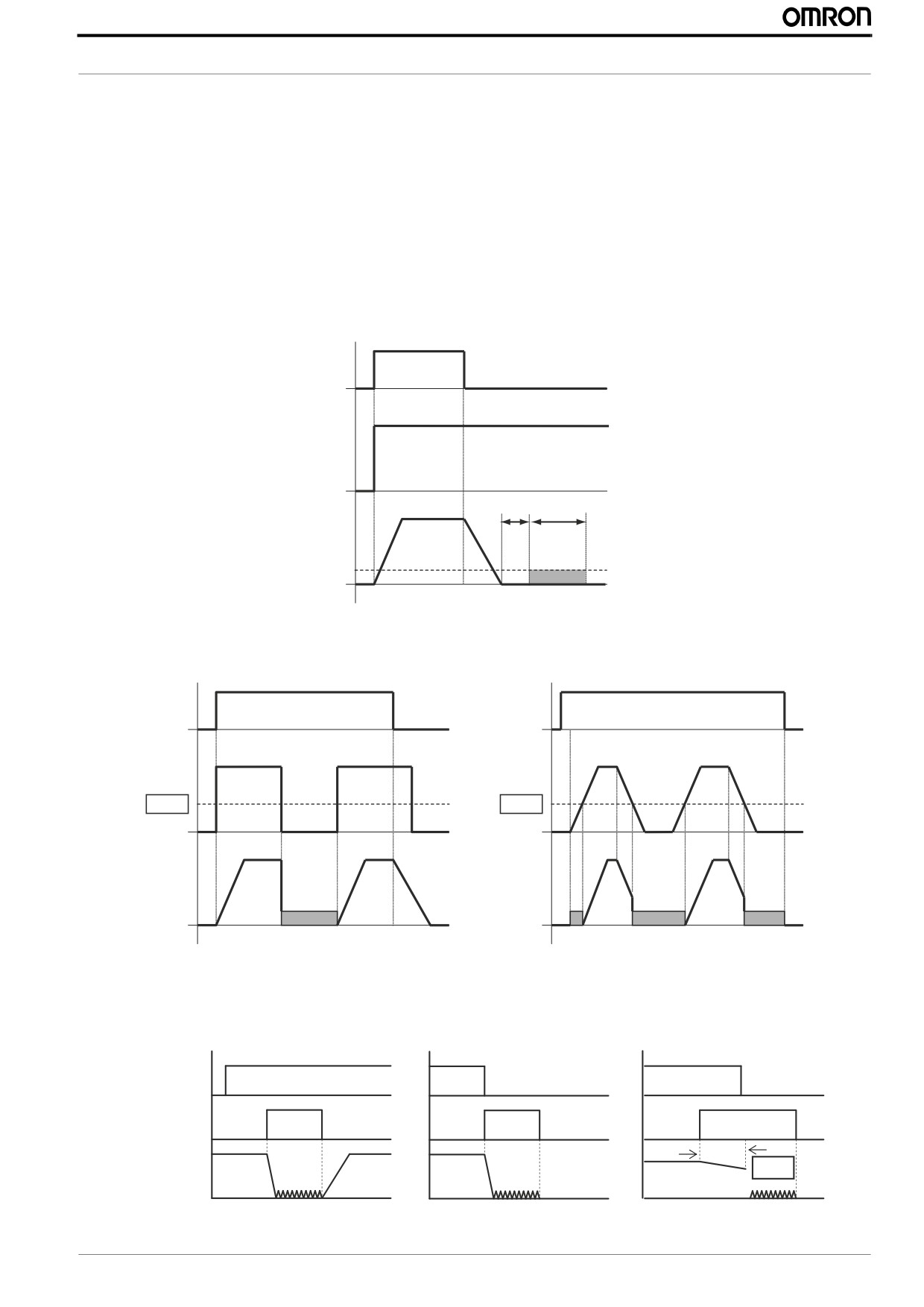

There are several modes available depending on the application requirements:

• Normal DC braking is used when A051 is set to “01” (Enable during stop) and the RUN command (FW/RV) is turned OFF,

at the moment that deceleration stops the DC brake starts with a settable power (A054) and duration (A055). Additionally is

possible to specify a wait time between the end of the ramp and the DC braking on parameter A053, during which the motor

will free run. If free-run is selected as stopping method the DC braking will start just when the Run commands turns OFF.

DC Brake at stop

FW

ON

F-SET

A053

A055

F-OUT

DB

A054

• DC braking by frequency detection can be selected setting a051 to “02” (Frequency detection). In this case DC braking oper-

ates when the output frequency comes down to the one you specified in A052 while the RUN command is still active. Exter-

nal DB and internal DC braking are invalid during the frequency detection mode.

FW

FW

ON

ON

F-SET

F-SET

A052

A052

F-OUT

F-OUT

DB

DB

DB

DB

Eample 1: Step change in F-SET

Example 2: Analog change in F-SET

• Last option is to trigger the DC injection by a digital input when the terminal (DB) is turned ON. Set parameters A053 and

A054 to setup this function. There are several cases depending on the motor rotation and Run command status.

FW or RV DI are ON

Run from operator

Run from operator with delay

1

1

1

[FW,RV]

0

0

0

1

1

1

[DB]

0

0

0

delay

A053

F-OUT

t

t

t

MX2 Quick Start Guide Draft

21

MX2 Quick Start Guide

DC braking at startup is also possible by independent setup of parameters A057 and A058. This is useful in aplications were load

should be totally stopped before starting the movement.

Parameter

Parameter Name

Description

A051

DC braking enable

Three options; select codes:

00... Disable

01... Enable during stop

02... Frequency detection

A052

DC braking frequency

The frequency at which DC braking begins, range is from the start

frequency (B082) to 60Hz

A053

DC braking wait time

The delay from the end of controlled deceleration to start of DC

braking (motor free runs until DC braking begins), range is 0.0 to

5.0 sec.

A054

DC braking force for

Level of DC braking force, settable from 0 to 100%

deceleration

A055

DC braking time for deceleration

Sets the duration for DC braking, range is from 0.0 to 60.0 seconds

A056

DC braking / edge or level

Two options; select codes:

detection for [DB] input

00... Edge detection

01... Level detection

A057

DC braking force at start

Level of DC braking force at start, settable from 0 to 100%

A058

DC braking time at start

Sets the duration for DC braking, range is from 0.0 to 60.0 seconds

A059

Carrier frequency during

Carrier frequency of DC braking performance, range is from 2.0

DC braking

to 15.0 kHz

Be careful to avoid specifying to long braking time or to hihg carrier frequency that can cause motor overheating. If you use DC

braking is recommended to use motors with a built-in thermistor and wire it to inverter’s thermistor input.

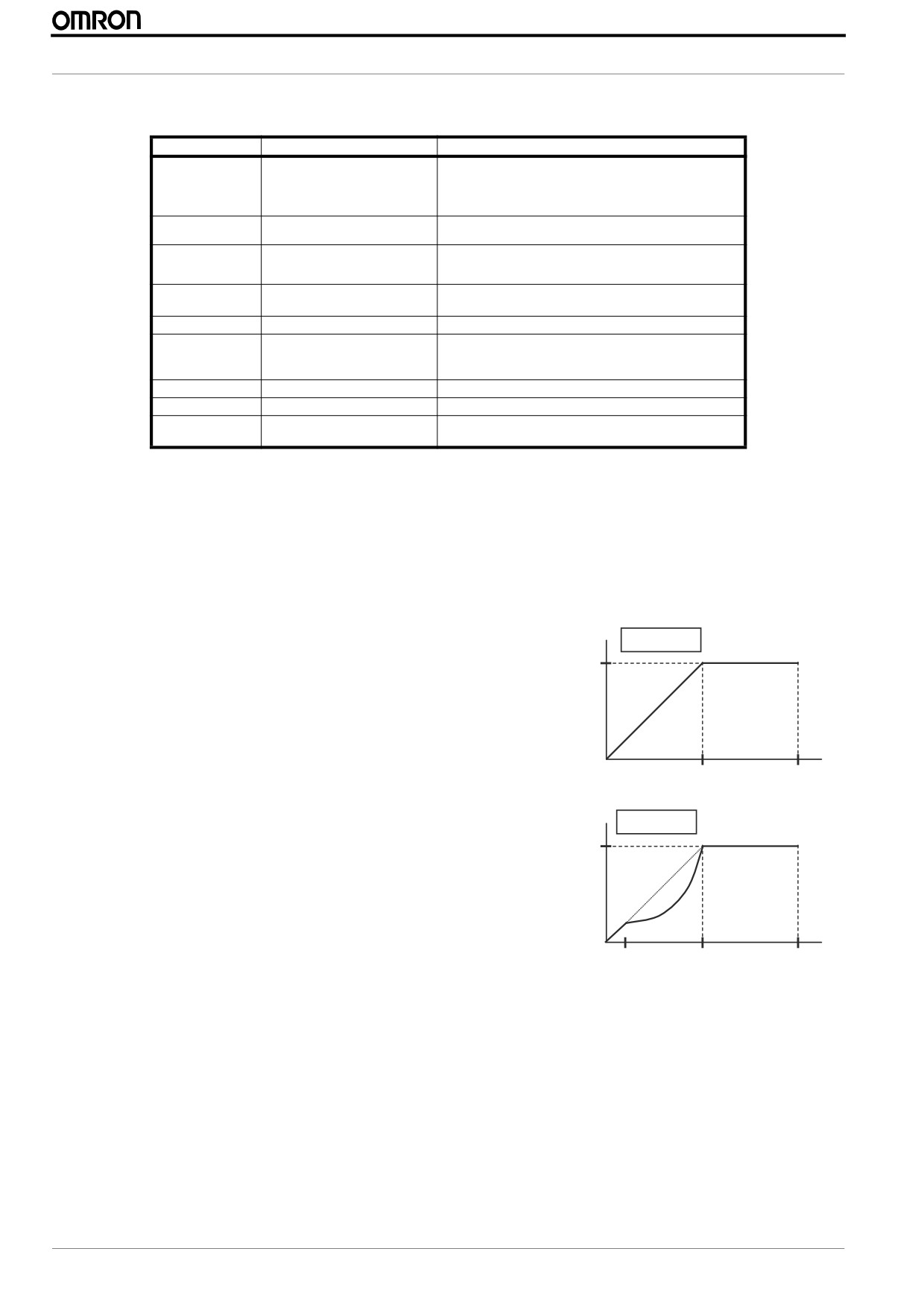

3.9 V/F Curve

The inverter generates the motor output according to the V/f algorithm selected on parameter A044. The factory default is Con-

stant torque (“00”). Review the following description to help you choose the best torque control algorithm for your application.

Review following description to help you choose the best torque control algo-

V

Constant torque

rithm for your application:.

A044 = 00

100%

• Constant and Variable (Reduced) Torque - The graph at right shows the

constant torque characteristic from 0 Hz to the base frequency A003. The

voltage remains constant for output frequencies higher than the base fre-

quency.

• Variable torque - The graph at right shows the variable (reduced) torque

Hz

curve, which has a constant torque characteristic from 0 Hz to 10% of the

0

Base

Max.

base frequency. This helps to achieve higher torque at low speed with

freq.

freq.

reduced torque curve at higher speeds.

V

A044 = 01

Variable torque

• Sensorless Vector Control - You can achieve high torque performance

(200% torque at 0.5 Hz of output frequency) without motor speed feedback

100%

but a god tuning of the motor is necessary to do it. Please remember to per-

form auto-tuning for this control method. (A044=”3”)

• Free V/F Control - The free V/F setting function allows you to set an arbi-

trary V/F characteristics by specifying the voltages and frequencies

Hz

(b100~b113) for seven points on the V/F characteristic curve (A044=”2”)

0

10% Base

Base

Max.

freq.

freq.

freq.

22

MX2 Quick Start Guide Draft

PROGRAMMING MX2

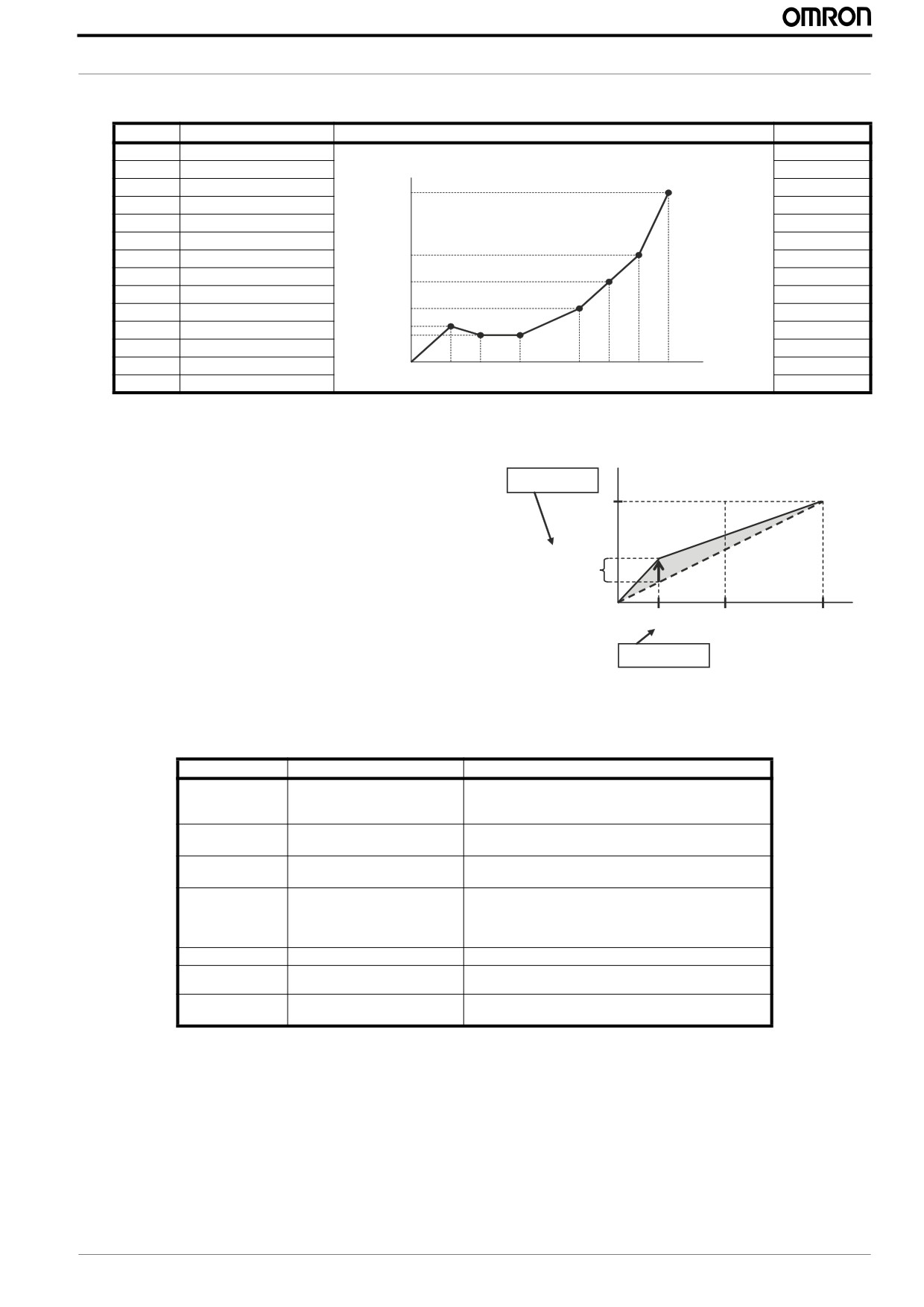

This table shows the details about the Free V/F control

Parameter

Parameter Name

Diagram

Range

b100

Free-setting V/F freq(1)

0 to b102(Hz)

b101

Free-setting V/F volt (1)

Output voltage (V)

0.0 to 800.0(V)

b102

Free-setting V/F freq(2)

b100 to b104(Hz)

b113

b103

Free-setting V/F volt (2)

0.0 to 800.0(V)

b104

Free-setting V/F freq(3)

b102 to b106(Hz)

b105

Free-setting V/F volt (3)

0.0 to 800.0(V)

b111

b106

Free-setting V/F freq(4)

b104 to b108(Hz)

b107

Free-setting V/F volt (4)

0.0 to 800.0(V)

b109

b108

Free-setting V/F freq(5)

b106 to b110(Hz)

b107

b109

Free-setting V/F volt (5)

0.0 to 800.0(V)

b101

b110

Free-setting V/F freq(6)

b108 to b112(Hz)

b103,b105

b111

Free-setting V/F volt (6)

Output freq.(Hz)

0.0 to 800.0(V)

b112

Free-setting V/F freq(7)

0 to 400.0(Hz)

0

b100 b102 b104

b106 b108

b110 b112

b113

Free-setting V/F volt (7)

0.0 to 800.0(V)

3.10 Torque boost function

Manual torque boost - Constant and Vairable torque algorithms

V

feature and asjustable torque boost curve that could help during

A042 = 5 (%)

the startup of load with very big inertia or friction. On those cases

100%

it may be necessary to increase the low frequency starting torque

characteristic by boosting the voltage above the normal V/F ratio.

A

Basically it attempsts to compensate for voltage drop in the motor

5% voltage

primary winding in the low speed range.

boost

(100%=A082)

Hz

0

Be aware that running the motor at a low speed for a long time can

1.8 Hz

30 Hz

fbase =

cause motor overheating and this is particularly true when manual

60 Hz

torque boost is activated and motor doesn’t have force ventilation.

A043 = 3 (%)

Automatic torque boost- Use the voltage compensation (A046)

and slip compensation (A047) to obtain a better performance under automatic torque boost mode (A041=01) ajusting the output

frequency and output voltage automatically depending on the load. The output voltage due automatic boost is added to the man-

ual torque boost voltage so both should be adjusted.

Parameter

Parameter Name

Description

A041

Torque boost select

Two options:

00... Manual torque boost

01... Automatic torque boost

A042

Manual torque boost value

Can boost starting torque between 0 and 20% above normal

V/f curve, range is 0.0 to 20.0%

A043

Manual torque boost frequency

Sets the frequency of the V/f breakpoint for torque boost,

range is 0.0 to 50.0%

A044

V/f characteristic curve

00... Constant torque

01... Reduced torque (1.7)

02... Free V/F

03... Sensorless vector (SLV)

A045

V/f gain

Sets voltage gain of the inverter, range is 20. to 100.%

A046

Voltage compensation gain for auto- Sets voltage compensation gain under automatic torque boost,

matic torque boost

range is 0. to 255.

A047

Slip compensation gain for auto-

Sets slip compensation gain under automatic torque boost,

matic torque boost

range is 0. to 255.

MX2 Quick Start Guide Draft

23

MX2 Quick Start Guide

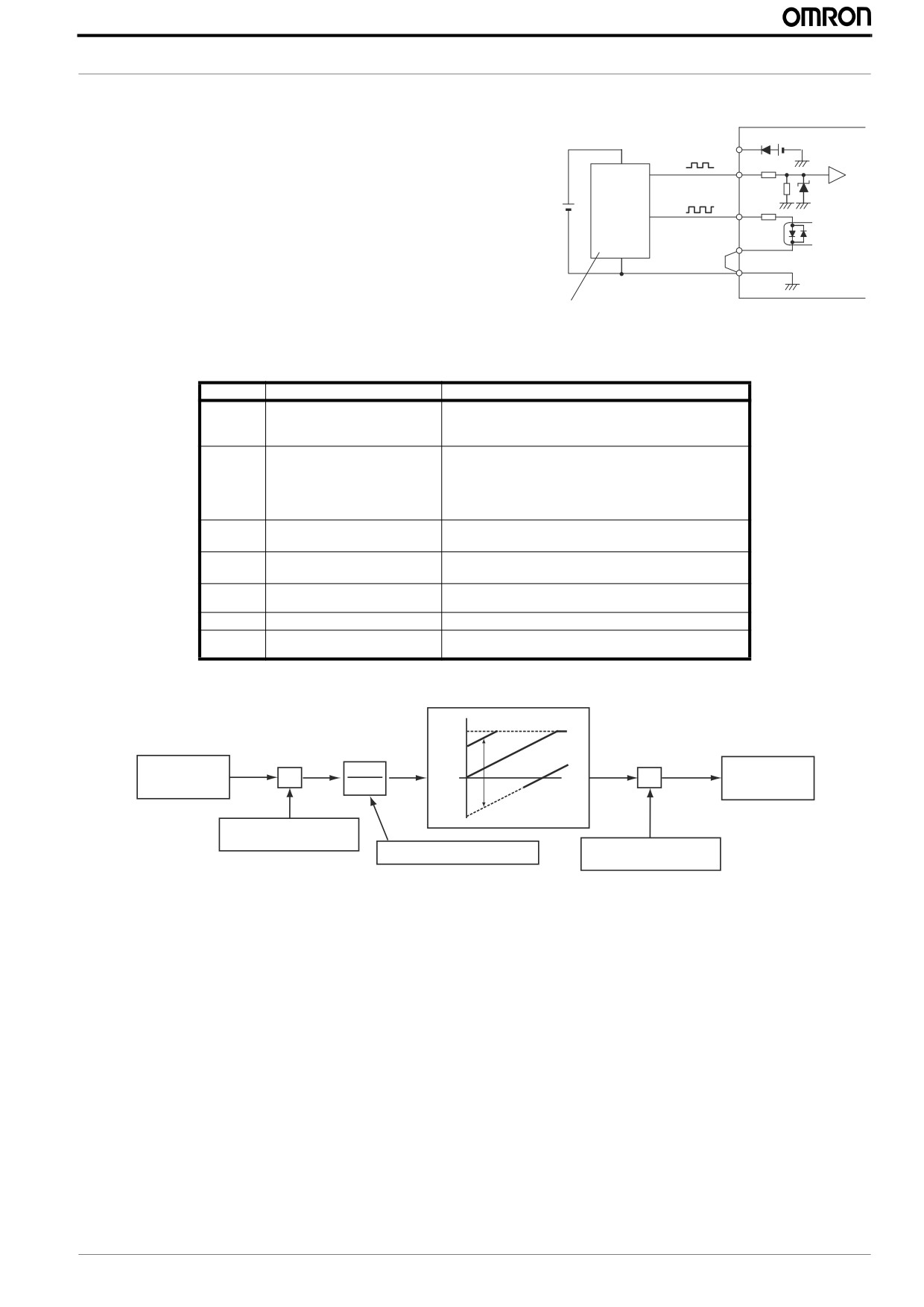

3.11 Analog inputs

MX2 provides two analog inputs, the input terminal group includes the [L], [OI],

AM H

O

OI

L

[O], and [H] terminals on the control connector, which provide for Voltage [O] or

+V Ref.

Current [OI] input. All analog input signals must use the analog ground [L].

Voltage input

If you use either the voltage or current analog input, you must select one of them

Current input

using the logic input terminal function [AT] analog type. Refer to next table for

A GND

details about the combinations between A005 and [AT] terminal. Remember that

you must also set A001=01 to select analog input as the frequency source.

V/I input select

A001

If [AT] function is not assigned to any digital input the inverter recognizes the

[AT]

Freq.

[AT] as OFF and [O]+[OI] will be used as analog input. In case either (O) or (OI)

setting

is to be referred, please ground the other.

A005

[AT] Input

Analog Input Configuration

AM H

O

OI

L

00

ON

[O]

OFF

[OI]

4-20 mA

02

ON

[O]

OFF

Integrated POT on external panel

0-10 V

03

ON

[OI]

1 to 2kΩ, 2 W

OFF

Integrated POT on external panel

For [O] input and using parameters A013 and A014 you could select the portion of

Max frequency

the voltage input range. Parameters A011 and A012 select the start and end fre-

quency of the converted output frequency range, respectively. When the line does

A012

A102

not begin at the origin (A011 and A013 > 0), then A015 defines whether the

A015=00

inverter outputs 0 Hz or the A011 specified frequency for analog input below A013.

A105=00

Parameter

Parameter name

Description

A015=01

A011

[O] start frequency

0.00 to 400.00

A105=01

A011

A012

[O] end frequency

0.00 to 400.00

A101

%

A013

[O] start voltage

0. to 100%

0

A014

[O] end voltage

0. to 100%

0%

A013

A014

100%

A015

[O] start frequency enable

00... Use offset (A011 value)

0V

A103

A104

10V

01..

Use 0Hz

Input scale

A101

[OI] start frequency

0.00 to 400.00

A102

[OI] end frequency

0.00 to 400.00

A103

[OI] start voltage

0. to 100%

A104

[OI] end voltage

0. to 100%

A105

[OI] start frequency enable

00... Use offset (A101 value)

01..

Use 0Hz

A016

Analog input filter

Range n = 1 to 31,

1 to 30 : ×2ms filter

31: 500ms fixed filter with ±0.1kHz hys.

24

MX2 Quick Start Guide Draft

PROGRAMMING MX2

3.12 Digital inputs

The function codes in the following table let you assign between a wide range of functions to any of the seven logic inputs for the

MX2 inverter. The functions C001 through C007 configure the terminals [1] through [7] respectively. The "value" of these partic-

ular parameters is not a scalar value, but it is a discrete number that selects one option from many available options.

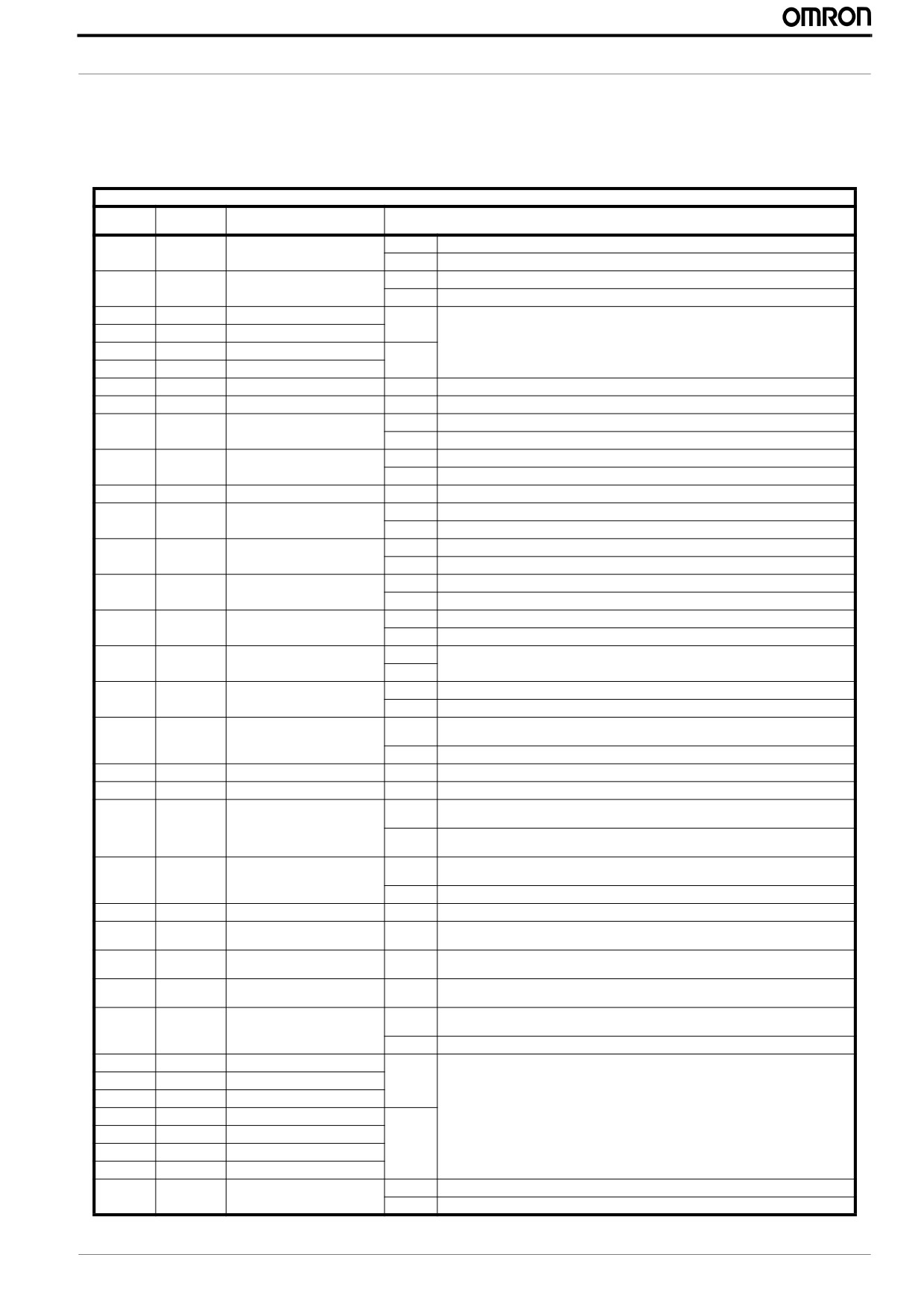

Input Function Summary Table

Option

Terminal

Function Name

Description

Code

Symbol

00

FW

FORWARD Run/Stop

ON

Inverter is in Run Mode, motor runs forward

OFF

Inverter is in Stop Mode, motor stops

01

RV

Reverse Run/Stop

ON

Inverter is in Run Mode, motor runs reverse

OFF

Inverter is in Stop Mode, motor stops

02

CF1

Multi-speed Select, Bit 0 (LSB)

ON

Binary encoded speed selection bit 3 to bit 0

03

CF2

Multi-speed Select, Bit 1

04

CF3

Multi-speed Select, Bit 2

OFF

05

CF4

Multi-speed Select, Bit 3 (MSB)

06

JG

Jogging

ON

Inverter is in Run Mode, output to motor runs at jog parameter frequency

07

DB

External DC braking

ON

DC braking will be applied during deceleration

08

SET

Set (select) 2nd motor Data

ON

The inverter uses 2nd motor parameters for generating frequency output to motor

OFF

The inverter uses 1st (main) motor parameters for generating frequency output to motor

09

2CH

2-stage Acceleration and Decel-

ON

Frequency output uses 2nd-stage acceleration and deceleration values

eration

OFF

Frequency output uses standard acceleration and deceleration values

11

FRS

Free-run Stop

ON

Causes output to turn OFF, allowing motor to free run (coast) to stop

12

EXT

External Trip

ON

When assigned input transitions OFF to ON, inverter latches trip event and displays E 12

OFF

No trip event for ON to OFF, any recorded trip events remain in history until reset

13

USP

Unattended Start Protection

ON

On powerup, the inverter will not resume a Run command

OFF

On powerup, the inverter will resume a Run command that was active before power loss

14

CS

Commercial power source swi-

ON

Motor can be driven by commercial power

tchover

OFF

Motor is driven via the inverter

15

SFT

Software Lock

ON

The keypad and remote programming devices are prevented from changing parameters

OFF

The parameters may be edited and stored

16

AT

Analog Input Voltage/Current

ON

Refer to Analog In put selection

Select

OFF

18

RS

Reset Inverter

ON

The trip condition is reset, the motor output is turned OFF, and powerup reset is asserted

OFF

Normal power-ON operation

19

PTC

PTC thermistor Thermal

ANLG

When a thermistor is connected to terminal [5] and [L], the inverter checks for over-tem-

Protection (C005 only)

perature and will cause trip event and turn OFF output to motor

OPEN

A disconnect of the thermistor causes a trip event, and the inverter turns OFF the motor

20

STA

Start (3-wire interface)

ON

Starts the motor rotation

21

STP

Stop (3-wire interface)

ON

Stops the motor rotation

22

F/R

FWD, REV

ON

Selects the direction of motor rotation: ON = FWD. While the motor is rotating, a change

(3-wire interface)

of F/R will start a deceleration, followed by a change in direction

OFF

Selects the direction of motor rotation: OFF = REV. While the motor is rotating, a change

of F/R will start a deceleration, followed by a change in direction

23

PID

PID Disable

ON

Temporarily disables PID loop control. Inverter output turns OFF as long as PID Enable is

active (A071=01)

OFF

Has no effect on PID loop operation, operates normally if PID Enable is active (A071=01)

24

PIDC

PID Reset

ON

Resets the PID loop controller. Main consequence is that integrator sum is forced to zero

27

UP

Remote Control UP Function

ON

Accelerates (increases output frequency) motor from current frequency

(motorized speed pot.)

28

DWN

Remote Control Down Function

ON

Decelerates (decreases output frequency) motor from current frequency

(motorized speed pot.)

29

UDC

Remote Control Data Clearing

ON

Clears the UP/DWN frequency memory by forcing it to equal the set frequency parameter

F001. Setting C101 must be set=00 to enable this function to work

31

OPE

Operator Control

ON

Forces the source of the output frequency setting A001 and the source of the Run com-

mand A002 to be from the digital operator

OFF

Source of output frequency set by A001 and source of Run command set by A002 is used

32

SF1

Multi-speed Select, Bit 1

ON

Bit encoded speed select, Bit 1 to Bit 7

33

SF2

Multi-speed Select, Bit 2

34

SF3

Multi-speed Select, Bit 3

35

SF4

Multi-speed Select, Bit 4

OFF

36

SF5

Multi-speed Select, Bit 5

37

SF6

Multi-speed Select, Bit 6

38

SF7

Multi-speed Select, Bit 7

39

OLR

Overload Restriction Source

ON

Perform overload restriction

Changeover

OFF

Normal operation

MX2 Quick Start Guide Draft

25

MX2 Quick Start Guide

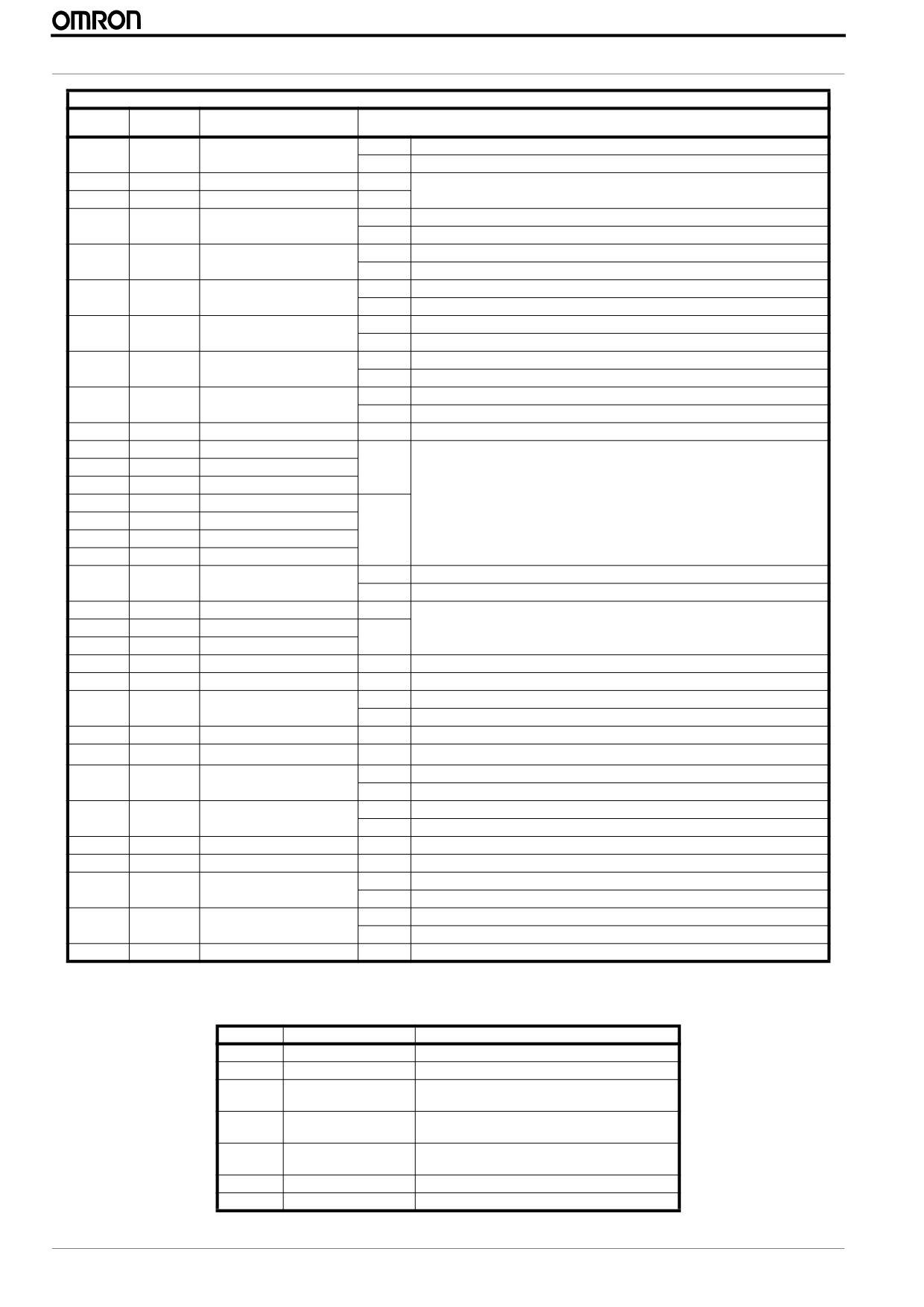

Input Function Summary Table

Option

Terminal

Function Name

Description

Code

Symbol

40

TL

Torque Limit Selection

ON

Setting of b040 is enabled

OFF

Max. torque is limited with 200%

41

TRQ1

Torque limit switch 1

ON

Torque limit related parameters of Powering/regen, and FW/RV modes are selected by the

combinations of these inputs.

42

TRQ2

Torque limit switch 2

OFF

44

BOK

Brake confirmation

ON

Brake confirmation signal received

OFF

Brake confirmation signal not received

46

LAC

LAD cancellation

ON

Set ramp times are ignored. Inverter output immediately follows the freq. command.

OFF

Accel. and/or decel. is according to the set ramp time

47

PCLR

Pulse counter clear

ON

Clear the position deviation data

OFF

Maintain the position deviation data

50

ADD

ADD frequency enable

ON

Adds the A145 (add frequency) value to the output frequency

OFF

Does not add the A145 value to the output frequency

51

F-TM

Force Terminal Mode

ON

Force inverter to use input terminals for output frequency and Run command sources

OFF

Source of output frequency set by A001 and source of Run command set by A002 is used

52

ATR

Enable torque command input

ON

Torque control command input is enabled

OFF

Torque control command input is disabled

53

KHC

Clear watt-hour data

ON

Clear watt-hour data

56

MI1

General purpose input (1)

ON

General purpose input (1) to (7) under Drive programming

57

MI2

General purpose input (2)

58

MI3

General purpose input (3)

59

MI4

General purpose input (4)

OFF

60

MI5

General purpose input (5)

61

MI6

General purpose input (6)

62

MI7

General purpose input (7)

65

AHD

Analog command hold

ON

Analog command is held

OFF

Analog command is not held

66

CP1

Multistage-position switch (1)

ON

Multistage position commands are set according to the combination of these switches.

67

CP2

Multistage-position switch (2)

OFF

68

CP3

Multistage-position switch (3)

69

ORL

Limit signal of homing

ON

Limit signal of homing is ON

70

ORG

Trigger signal of homing

ON

Starts homing operation

73

SPD

Speed/position changeover

ON

Speed control mode

OFF

Position control mode

77

GS1 *

GS1 input

ON

EN60204-1 related signals: Signal input of "Safe torque off" function.

78

GS2 *

GS2 input

OFF

81

485

Start EzCOM

ON

Starts EzCOM

OFF

No execution

82

PRG

Executing Drive programming

ON

Executing Drive program

OFF

No execution

83

HLD

Retain output frequency

ON

Retain the current output frequency

84

ROK

Permission of Run command

ON

Run command permitted

85

EB

Rotation direction detection

ON

Forward rotation

(C007 only)

OFF

Reverse rotation

86

DISP

Display limitation

ON

Only a parameter configured in b038 is shown

OFF

All the monitors can be shown

255

no

No function

ON

(input ignored)

All this functions could be assigned to any of the multi-function inputs on parameters C001 to C007, select if the input will be

normally open or normally close and the response time of the input.

Parameter

Parameter name

Description

C001

Input [1] function

Select input terminal [1] function

C002

Input [2] function

Select input terminal [2] function

C003

Input [3] function

Select input terminal [3] function

[GS1 assignable]

C004

Input [4] function

Select input terminal [4] function

[GS2 assignable]

C005

Input [5] function

Select input terminal [5] function

[PTC assignable]

C006

Input [6] function

Select input terminal [6] function

C007

Input [7] function

Select input terminal [7] function

26

MX2 Quick Start Guide Draft

PROGRAMMING MX2

Parameter

Parameter name

Description

C011

Input [1] active state

Select logic conversion, two option codes:

C012

Input [2] active state

00... normally open [NO]

01... normally closed [NC]

C013

Input [3] active state

C014

Input [4] active state

C015

Input [5] active state

C016

Input [6] active state

C017

Input [7] active state

C160

Input [1] response time

Sets response time of each input terminal,

set range:

C161

Input [2] response time

0 (x 2 [ms]) to 200 (x 2 [ms])

C162

Input [3] response time

C163

Input [4] response time

C164

Input [5] response time

C165

Input [6] response time

C166

Input [7] response time

d005

Intelligent input

ON

terminal status

OFF

7

6

5

4

3

2

1

Terminal numbers

An input terminal configured for option code 18 ([RS] Reset command) cannot be configured for normally closed operation.

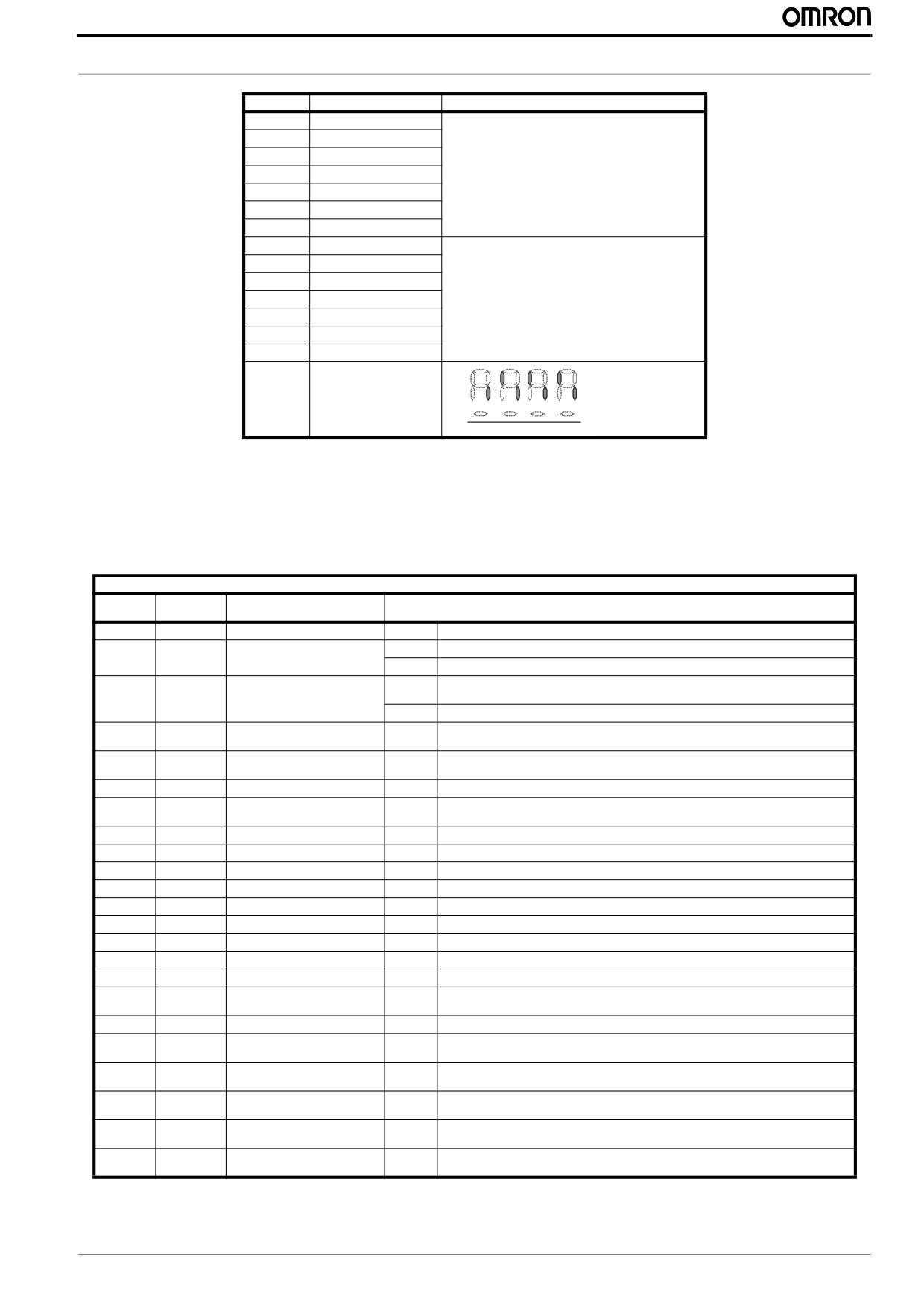

3.13 Digital outputs

Function codes in the following table let you assign different options into logical outputs (terminals [11],[12] and [AL]) on

parameter C021, C022 and C026..

Input Function Summary Table

Option

Terminal

Function Name

Description

Code

Symbol

00

RUN

Run Signal

ON

When the inverter is in Run Mode

01

FA1

Frequency Arrival Type 1-

ON

When output to motor is at the set frequency

Constant Speed

OFF

When output to motor is OFF, or in any acceleration or deceleration ramp

02

FA2

Frequency Arrival Type 2-

ON

When output to motor is at or above the set freq., even if in accel (C042) or

Over frequency

decel (C043) ramps

OFF

When output to motor is OFF, or at a level below the set frequency

03

OL

Overload Advance Notice

ON

When output current is more than the set threshold (C041) for the overload sig-

Signal 1

nal

04

OD

Output Deviation for PID

ON

When PID error is more than the set threshold for the deviation signal

Control

05

AL

Alarm Signal

ON

When an alarm signal has occurred and has not been cleared

06

FA3

Frequency Arrival Type 3-

ON

When output to motor is at the set frequency, during accel (C042) and decel

Set frequency

(C043).

07

OTQ

Over/under Torque Signal

ON

Estimated motor torque exceeds the specified level

09

UV

Undervoltage

ON

Inverter is in Undervoltage

10

TRQ

Torque Limited Signal

ON

Torque limit function is executing

11

RNT

Run Time Expired

ON

Total running time of the inverter exceeds the specified value

12

ONT

Power ON time Expired

ON

Total power ON time of the inverter exceeds the specified value

13

THM

Thermal Warning

ON

Accumulated thermal count exceeds the C061 set value

19

BRK

Brake Release Signal

ON

Output for brake release

20

BER

Brake Error Signal

ON

Brake error has occurred

21

ZS

Zero Hz Speed Signal

ON

Output frequency falls below the threshold specified in C063

22

DSE

Speed Deviation Excessive

ON

Deviation of speed command and actual speed exceeds the specified value

P027.

23

POK

Positioning Completion

ON

Positioning is completed

24

FA4

Frequency Arrival Type 4-

ON

When output to motor is at or above the set freq., even if in accel (C045) or

Over frequency

decel (C046) ramps

25

FA5

Frequency Arrival Type 5-

ON

When output to motor is at the set frequency, during accel (C045) and decel

Set frequency

(C046).

26

OL2

Overload Advance Notice

ON

When output current is more than the set threshold (C111) for the overload sig-

Signal 2

nal

27

ODc

Analog Voltage Input Dis-

ON

When the [O] input value < B070 setting (signal loss detected)

connect Detection

28

OIDc

Analog Current input Dis-

ON

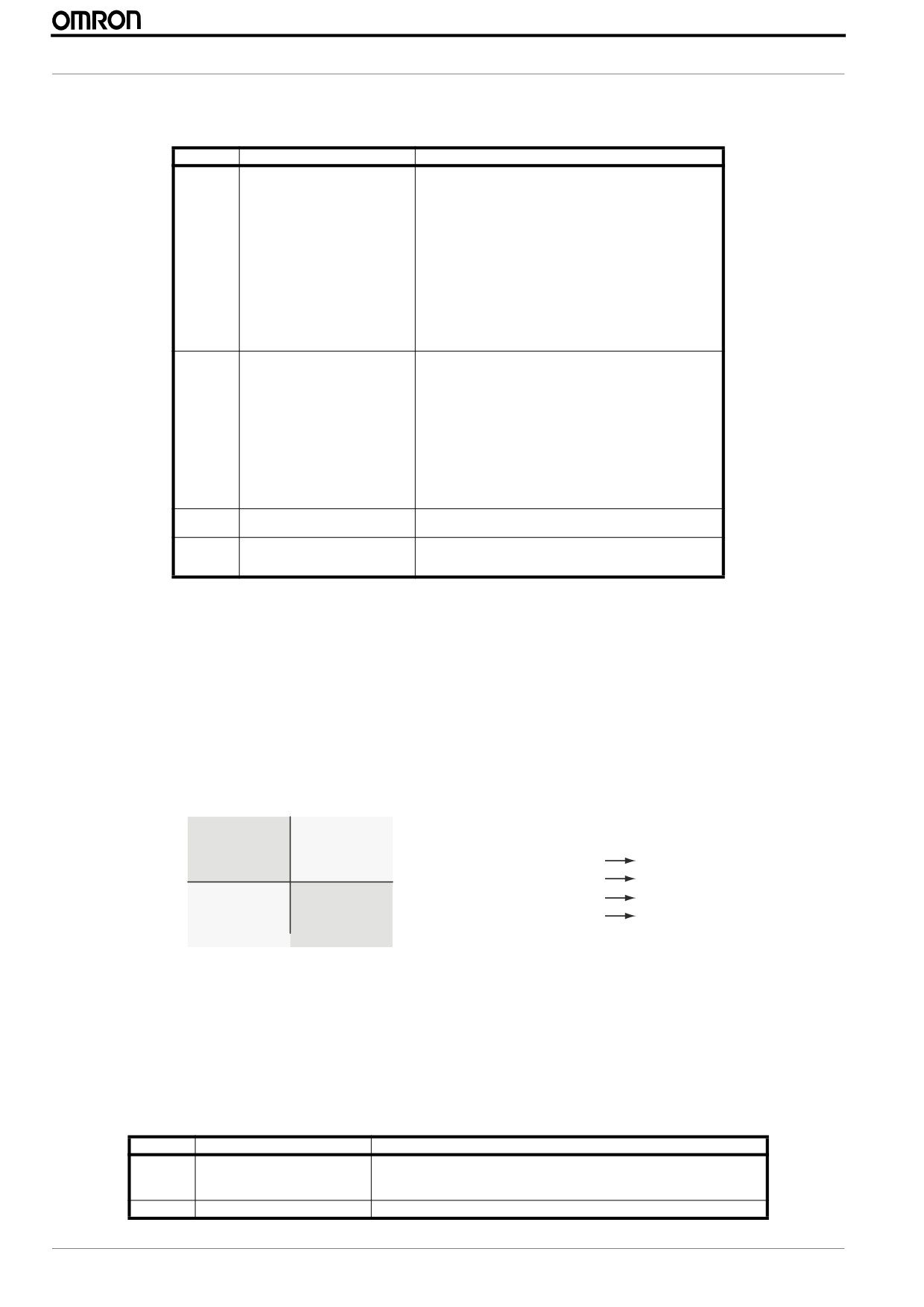

When the [OI] input value < B071 setting (signal loss detected)